Inventory management 101: All you need to know from techniques to reporting

Inventory management is important, doing it effectively, even more so. Let’s understand and apply it.

Inventory management is the foundation of any retail or distribution business. If the orders are not reaching customers on time, your profits start dwindling along with your customers. Proper planning to source from the right people, at the right time, right price, and right quantity determines how smoothly everything works.

What is inventory management?

Inventory management is the planning activities to control procurement, order fulfillment, and other activities to ensure that the right inventory is available in storage. Let’s understand what it really means. Consider that you’re running a retail or even a manufacturing business. The first thing you need to do is procure goods or raw materials from the best suppliers. Once the quotations and prices are accepted by you and your suppliers, you get the goods in exchange for money. You store the goods in warehouses with different proximities according to the requirement of those items.

When the customer places an order, you either wrap and send single items, put together a kit, or get ready for manufacturing. Then you ship the items to customers. Now, in a running business, you need to figure out things like which supplier to choose, lead times of items to reach your warehouses, how much quantity to stock, which customers to sell, which units to use, and many other things that come under inventory management.

Although inventory management is an umbrella term for a variety of activities, the key objective of all the planning is to maintain a balance between stock surplus and shortage. Note that inventory management is definitely NOT the same as inventory control, we’ll see more on this later.

Why is inventory management important?

According to a 2017 report by wasp barcode, 43% of small businesses don’t track their inventory or have a manual process for it.

Not implementing inventory management is like buying your groceries without a plan. While doing the latter will at worst cause extra monthly expenses and adding a few kilos to you, not having proper inventory management will actually hurt your business. How? Let’s consider an example.

Imagine that you’re running your retail or distribution business as usual. Items come in from the first or second supplier you review, they send at a leisurely pace and you have orders upon orders from customers piled up. You don’t have proper records of when procured items are expected, how much storage you have, the condition of existing inventory, priority of delivering items to customers, etc. And most importantly, you don’t know how much to order when.

Here, spreadsheets don’t help much since they’re a mess for any serious business with hundreds of inventory items. Without a proper inventory management plan, you run the risk of accumulating losses in the form of carrying costs and without a proper system, you waste your time figuring out things that you could get in seconds with a few clicks. These problems are solved with good planning and software but it’s important to note here that inventory management is not a one time solution, it’s a continuous process.

Inventory management benefits

Before we get into the inventory management techniques, let’s glance over a few benefits of Inventory management:

- Avoid wastage and dead stock: By managing your inventory quantities and reordering promptly you avoid excess stock and wasting goods that stay idle or expire.

- Optimal inventory levels: This means having just the right quantity of items at all times. Not low enough that there’s a shortage and lost sales but also not high enough that there’s idle inventory. Usually done with software that takes into account relevant parameters like threshold, lead time, demands, and safety stock.

- Customer retention: Well managed inventory results in short turnaround times for orders. When the orders are shipped to customers on time, they stay happy and buy from you again.

8 Inventory management techniques

Many confuse operational tasks for inventory management techniques. With the key idea that inventory management is about planning for inventory levels, let’s see the common inventory management techniques used.

1. Reordering

For ideal inventory management, planning for when to reorder is the most important aspect, which is, the reorder point.

A reorder point is the minimum amount of inventory quantity reached at which point it’s time to reorder stock. In simple terms, it’s the quantity threshold at which more stock needs to be ordered. Now, a reorder point formula calculates this point. You’d think if it’s just a threshold number, why bother with a formula? Because there are two more parameters accounted for reordering—lead time and daily stock usage. So the reorder point formula becomes:

Reorder Point (ROP) = Maximum lead time (days, weeks, or months) x Maximum daily stock usage (units used) + Safety stock

Where, the formula for safety stock is:

Safety stock = _ (Maximum daily stock usage x Maximum lead time) - (Average daily stock usage x Average lead time)_

Daily stock usage = units (kilos/litres/units)

This formula will give you the number of units at which you should reorder inventory. In case your business doesn’t need safety stock, simply remove it from the equation. In the ROP formula, some businesses also use ‘average lead time’ and ‘average daily stock usage’ instead of maximum lead time and stock usage. Any experienced inventory manager should be able to determine what’s better suited for your business between maximum and average.

Note that in the formula for safety stock, maximum daily stock usage and average daily stock usage can also be called sales/orders, the important thing to note here is that this is the quantity that leaves your warehouse every day.

Safety stock

To avoid any doubt, let’s also understand what safety stock is. In an ideal world, you’ll procure goods and use them. But this rarely happens, natural disasters strike, goods get lost, negligence happens, and so on. So, you should never really order the exact amount of goods needed, you need a small surplus, i.e., safety stock.

Storing safety stock also introduces carrying costs which you should account for when selling goods.

2. ABC method

The inventory is classified into three categories namely A, B, and C. Where category A is the highest contributor to revenue 70-80%, B items contribute 15-25% of the total revenue, and C category items contribute about 5%. Now, based on what you sell, category A could be big ticket items or a large quantity of your most popular items. Understanding and classifying the inventory using the ABC method allows you to plan which items to reorder and when.

3. Just in time (JIT) inventory management

Similar to make to order in manufacturing, JIT inventory management is used to eliminate wastes and minimize carrying costs. Most B2B industries follow make to order or engineer to order due to the nature of goods produced and sold. Many of them are expensive to produce and store, think large machinery, expensive testing kits, large quantities of machines, etc. It’s not practical to make them to stock. The speed of your production cycle, lead time of raw materials, and customer expectations are important factors to consider before practicing JIT inventory.

In B2C, with drop shipping becoming popular, more distributors there are leaning towards JIT. However, since no stock is held, there are risks like lost sales and risk of procuring at high prices.

4. Backordering

Accepting orders even when you don’t have inventory to fulfill it is known as backordering. It’s a common practice in B2B industries but also in B2C as seen in the popular example—iPhones. Planning to set one or more items with irregular demands on backorder can save you a lot of money since you don’t hold inventory. Managing backordering can be a bit trick, to know more check out the blog on backordering.

5. Consignment

In wholesale, consignment is a common practice where the wholesaler/distributor sends stock to the retailer but the retailer does not pay the distributor yet. The retailer pays the distributor only when the items are sold. Said payment can be monthly or any other interval as agreed upon by both parties. As a distributor, it may seem like you're taking all the risk, and you are but there are also some benefits to consignments. You can test new products in the market, get free marketing from the retailer, free up storage by consigning to multiple retailers, and understand how the market responds to your products.

6. Dropshipping

We saw how JIT, backordering, and consignment minimize carrying costs but here’s a technique that eliminates it altogether. Dropshipping means accepting orders from your customers and fulfilling them directly via shipments from your supplier. You don’t hold any inventory this way and save a lot on storage costs. The benefit for your suppliers is more channels to sell their products.

7. Stock counting vs cycle counting

Stock counting or stocktaking is counting the whole inventory regularly, it’s time consuming but provides more accurate information on the inventory levels. In cycle counting, only a part of the whole inventory is counted. It’s a good practice to change up the schedule and count one category at a time. Cycle counting saves time while ensuring that quantities in the shelves match the system.

8. Inventory forecasting

Forecasting demands and adjusting inventory levels is important to avoid problems like wastage and dead stock. Needless to say, you’ll need more than spreadsheets to do this effectively. Parameters like current stock usage, sales orders, shelf life, etc., are taken into account for inventory forecasting.

7 KPIs for inventory management

Key performance indicators are a way to measure whether your inventory management is going in the right direction. Let’s look at a few KPIs that’ll help you measure the effectiveness of your inventory management.

1. Carrying costs

The money you’ve spent on inventory that’s sitting idle is called carrying costs. High carrying costs are an indicator of bad planning, forecasting, and overstocking. Ideally, you want to keep this at a minimum if not zero. This is the most important KPI that reflects how well your inventory management is working.

2. Stockouts

An important question to ask is “how many times did the inventory stockout?”. Just like surplus inventory causes carrying costs, too little inventory causes stockouts which stops production of items or order fulfillment depending on your business.

3. Dead stock

Dead stock is stock that cannot be sold which is a result of surplus inventory. When excess inventory for which there is no demand sits in storage over a long time, the stock is counted as dead. While not all units always sell, a high number of dead stock units is a reflection of poor planning and stock replenishment strategy.

4. Inventory shrinkage

Inventory shrinkage is a situation when the actual physical stock is less than the quantity listed in the inventory management system. High inventory shrinkage means that you’re accepting a lot of defective products, items are getting damaged, stolen, or there’s miscounting.

5. Inventory turnover

The rate at which inventory is sold and restocked is known as inventory turnover. A high turnover rate is an indicator of good efficiency. If the turnover rate is low, it means that you’re overstocking and not selling fast enough. The formula for inventory turnover is:

Cost of goods sold / Average Inventory.

6. Sales return rate

This is the rate of items sent back to you by customers. Customers return items when they’re not satisfied. Reasons include the product being faulty or not matching expectations. Understanding customer needs and enforcing quality standards keeps this rate low. To calculate sales return rate use the formula:

Number of items returned / Number of items shipped.

7. Supplier quality

Whether you’re a reseller or manufacturer, you procure items from suppliers. It’s important to rate your suppliers based on the quality of items they send and also lead times. By scoring multiple suppliers and maintaining a scorecard, you can decide who gets most of your business in return for high quality and timely fulfillment of procurements.

Inventory management best practices

Now let’s look at some best practices for inventory management that’ll prevent you from making common mistakes.

1. Identify your inventory management method

Depending on the number and variety of items you sell from your inventory, you’ll be following one of these inventory management types to review inventory:

- Perpetual inventory: Also known as a continuous inventory review system, the inventory count is updated on every stock movement or transaction. The benefit is high accuracy but the downside is more work to count each time and update physical count with system recorded count.

- Periodic inventory: The inventory count is updated on fixed intervals like 2 weeks or 3 months. Based on review and updates, new stock may be ordered. The benefit is less work but the downside could be running out of inventory if you don’t stock enough.

2. Factor in safety stock

You should always order some extra stock more than you need, especially when your business has to stock inventory regularly. Yes, efficiency is important but so is accounting for unforeseen circumstances. Market demands can fluctuate, mishaps occur, goods can be defective. Such situations can leave you with insufficient stock to fulfill your orders. But also, when pricing your goods, the extra cost of safety stock, shipping damages, etc, should be factored into your selling price.

3. Set up quality standards

Setting up quality standards and processes for inspection is crucial to ensure good items enter your warehouse and reach your customers. Depending on whether you’re a retailer or manufacturer, quality inspections should be standard at various stages of the supply chain. At least a few samples from each batch or group of items should be inspected when they enter your warehouse and leave your warehouse. The inspection criteria like color, shape, lights, etc., are determined depending on the goods transacted. Having quality standards minimizes defects and inventory variance. Quality in the context of inventory management is more about standardization and defining standards for what are good quality items for your company.

4. Keep cash flow in check

It’s easy to get carried away by demand spikes and overstock your warehouses. But, after docking a large procurement, if your customers aren’t buying, you’re left with a huge pile of inventory that’s not being sold. This adds to carrying costs and tampers with your cash flow and ability to manage other parts of your business.

5. Use software, not spreadsheets

According to the report, we saw earlier, only 57% of businesses in the US use software or spreadsheets to manage their inventory. That leaves us with 43% of businesses that use nothing or pen and paper! We’ll not even talk about why pen and paper is inefficient. Spreadsheets on the other hand work alright with a few hundred orders and a couple of bins of inventory. But to efficiently manage your labor, warehouses, stock, shipments, customers, etc., you need a proper inventory management software that allows you to access relevant information and move around items in a few clicks. All data is also centralized which means you’ll not be squandering over which spreadsheets to edit.

Inventory management comparisons

Inventory control, warehouse management, and even asset management are terms often heard along with inventory management. While they have some common factors, let’s see how they’re different from one another.

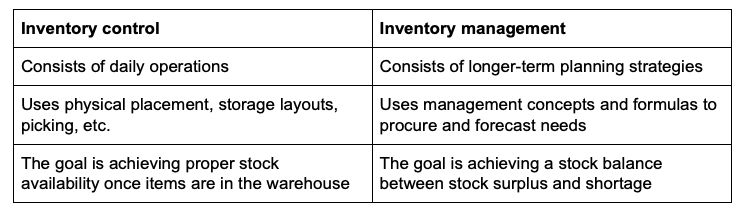

1. Inventory management and control

Although they sound similar, inventory management is a broader concept that encompasses everything from stock procurement to selling it to the customer. Inventory control is more about daily operations that take place in warehouses to prevent inefficient movement, inventory expiration, wastage due to bad quality, etc.

Ok, that probably didn’t draw clear distinctions, this table will:

2. Inventory management vs warehouse management

Warehouse management is a larger operation that involves inventory management. If you’re running a large company with multiple warehouses, you’d consider getting a dedicated warehouse management system with features to record docking, putaway, warehouse logic, RFID, driver navigation, shipment notifications, etc. Inventory management is broader with features to procure, manage inventory and suppliers, record stock levels, packing, locations and set up ordering systems. A dedicated warehouse management system is better suited for large companies with lots of warehouses to manage.

3. Inventory management vs asset management

An asset is a moveable or immovable property owned by a company. In the context of inventory management, let’s consider assets like computers, vehicles, phones, stationery, electronic accessories, etc. The key difference here being assets are items that your company owns and inventory are the items that are sold for cash. Features also differ between these software where asset management software will have features to calculate asset depreciation, movement, allocation, etc. To avoid data fragmentation with multiple software, an all inclusive ERP system is a better choice.

How does an inventory management system work

Now let’s see inventory management in action with the help of ERPNext. This section will showcase essential features like managing supplier quotations, automatic replenishment, serialization, reporting, etc.

1. Supplier quotations and portal

Choosing your best suppliers starts with trying out different suppliers first by getting quotes from them. You could do this the old fashioned way via phone calls and emails or directly send them a link where they can enter their quote. An email will land on the supplier’s email inbox.

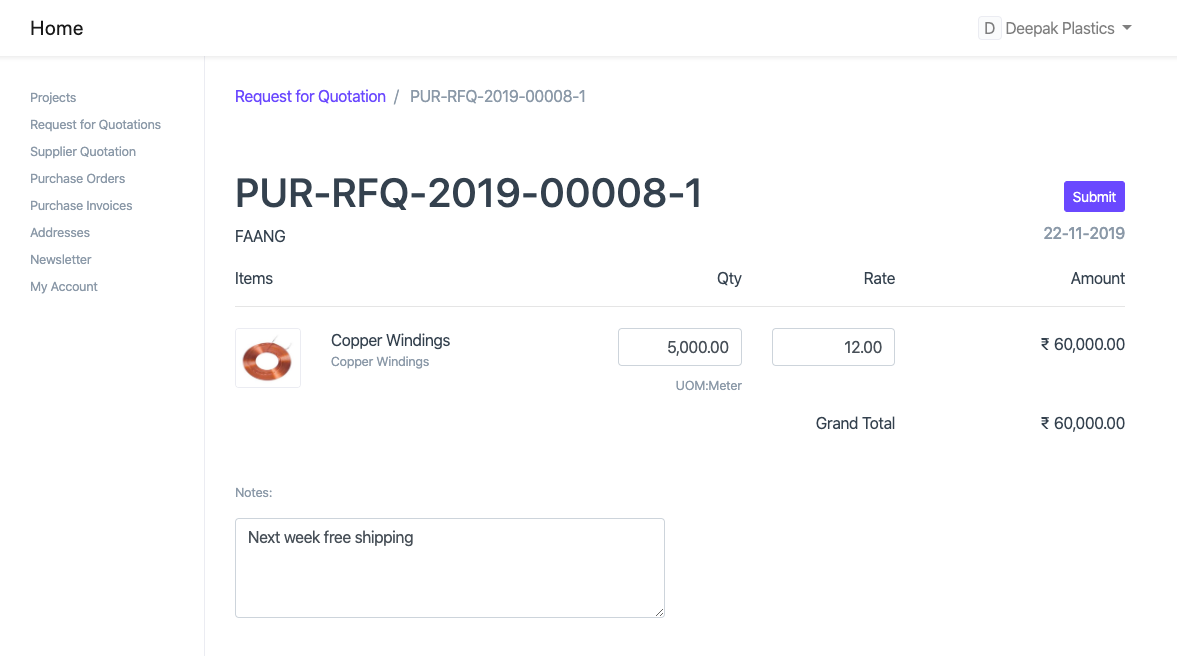

After the supplier clicks on the link, they can enter their quote like this:

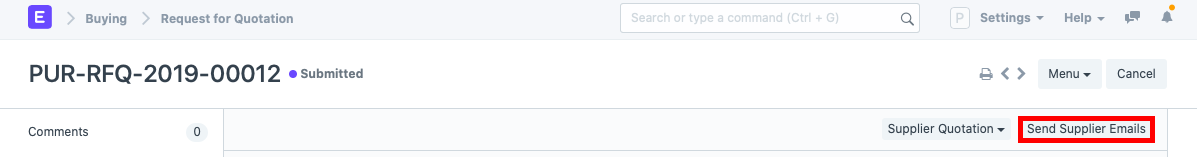

For this to happen, there are a few steps that need to be configured:

- The supplier is a portal user and hence cannot access your ERPNext account’s details.

- The supplier should be stored as a contact with a valid email address in your account.

- In the Request for Quotation form, after entering the supplier and item details, click on the ‘Send Supplier Emails’ button. This will send the supplier an email with a link which they can use to submit their quote.

Now you’ll have quotations from all your suppliers in one place to compare and choose what’s best for your business.

2. Reordering or replenishment

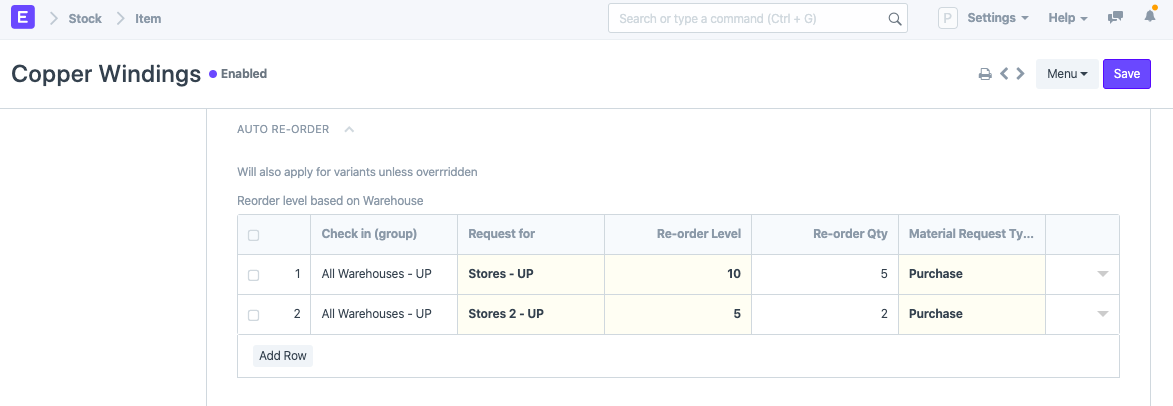

Setting a threshold for reordering is the best way to ensure you’re neither overstocked nor stocked out. You can allow ERPNext to automatically generate Material Requests when the threshold is hit.

In the following example, the auto reorder feature will do the following:

- Check quantity in All Warehouses.

- Request new items for Stores and Stores 2 (since there are two rows).

- When reorder level is 10 and 5 respectively, order 5 and 2 items.

- The method for procuring the new items is ‘Purchase’, it could be other types depending on whether you buy or make the items.

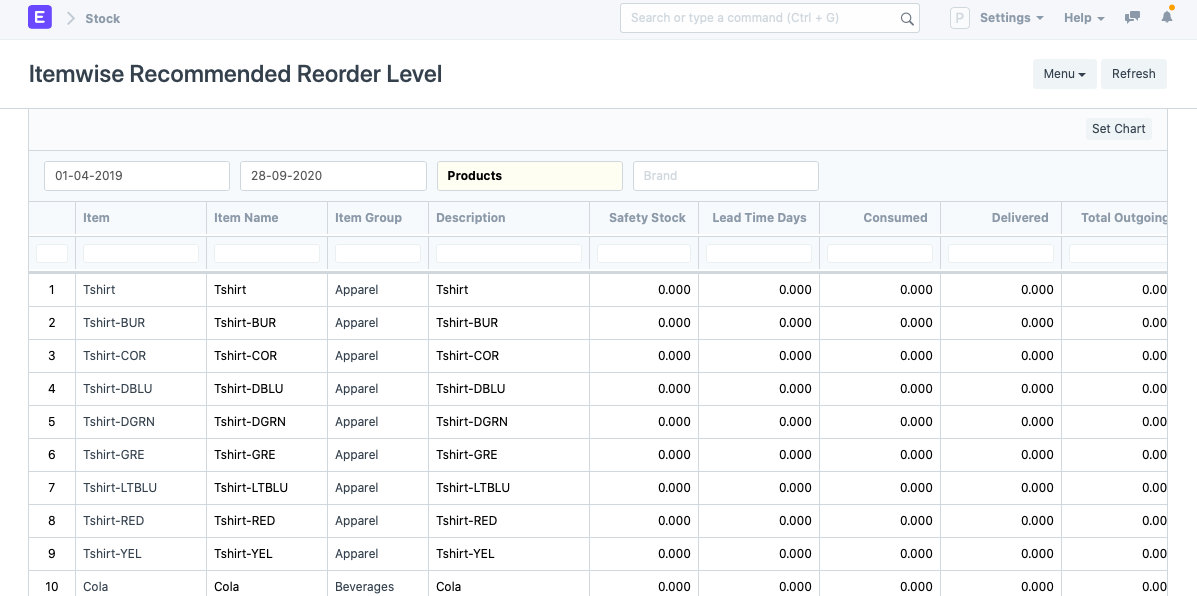

The Itemwise Recommended Reorder Level report in ERPNext shows all the details you need like safety stock, lead time in days, consumed quantity, delivered quantity, total outgoing, average daily outgoing, and finally the reorder level set in the item form. From this report, you can also gather which items sell more i.e., the ones you should procure more of and the ones that don’t get sold so you can consider scrapping them from your warehouses altogether.

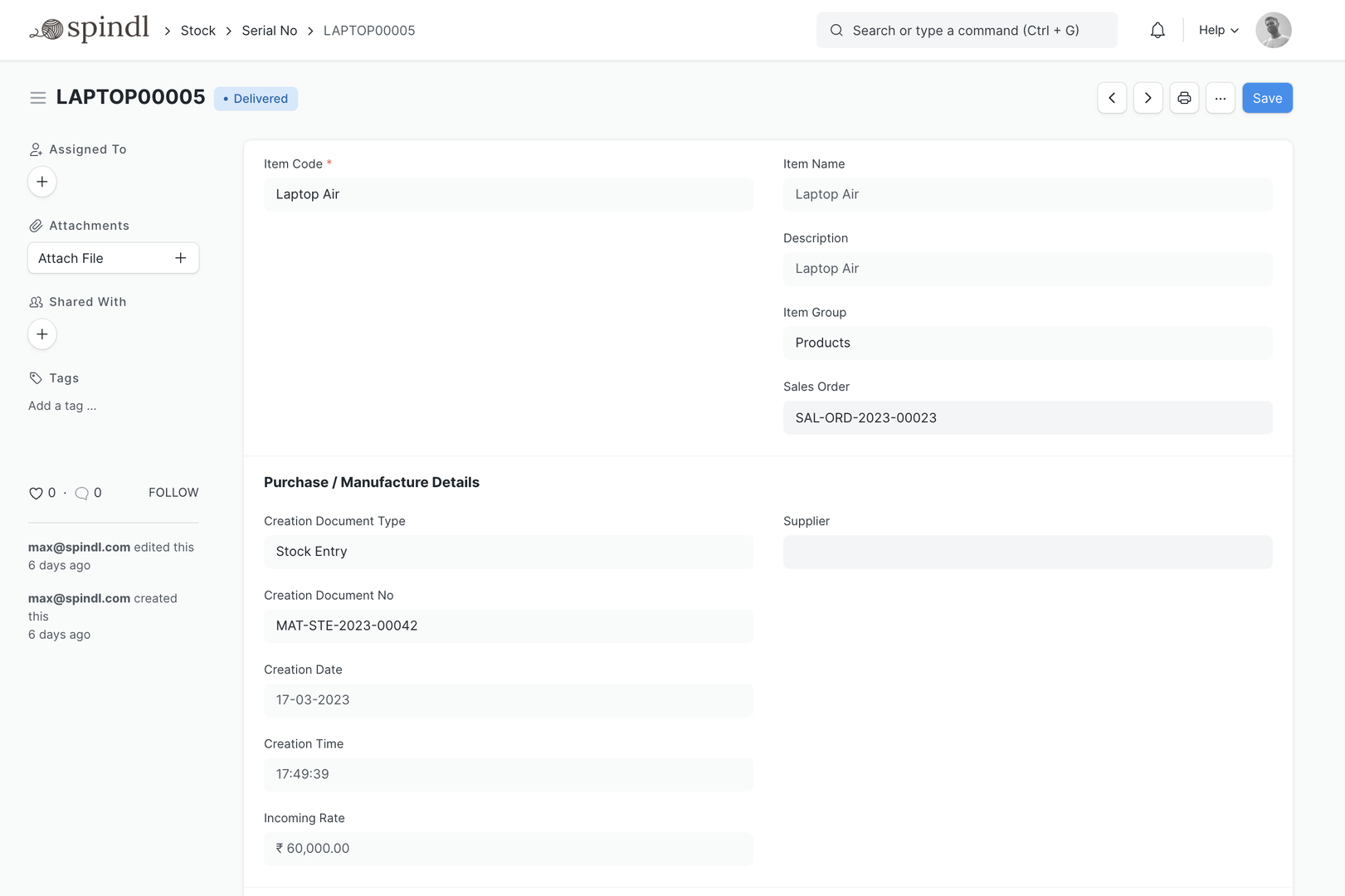

3. Serializing inventory

By serializing goods, you can track warranty status appropriately. It also helps in quickly processing repairs and replacements.

4. Reporting

In inventory management, planning and making decisions are done based on data from your current inventory levels, expiry, accounts, sales, and demands. Reports with relevant data and charts help make better inventory management decisions.

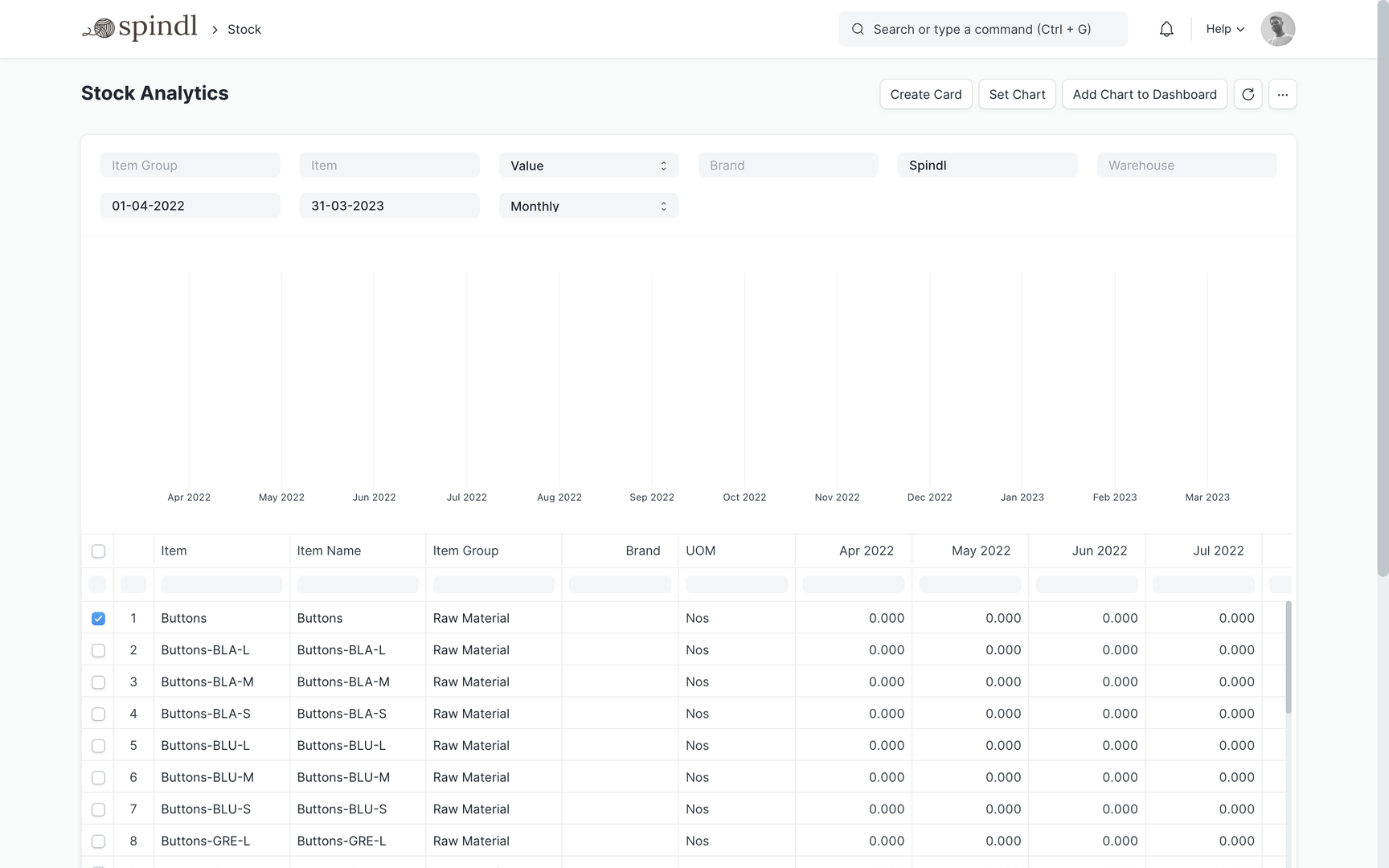

Stock analytics

Getting a bird’s eye view of all your stock analytics and their sales helps understand which items are being sold when. Using this information, you can adjust your procurement and sales.

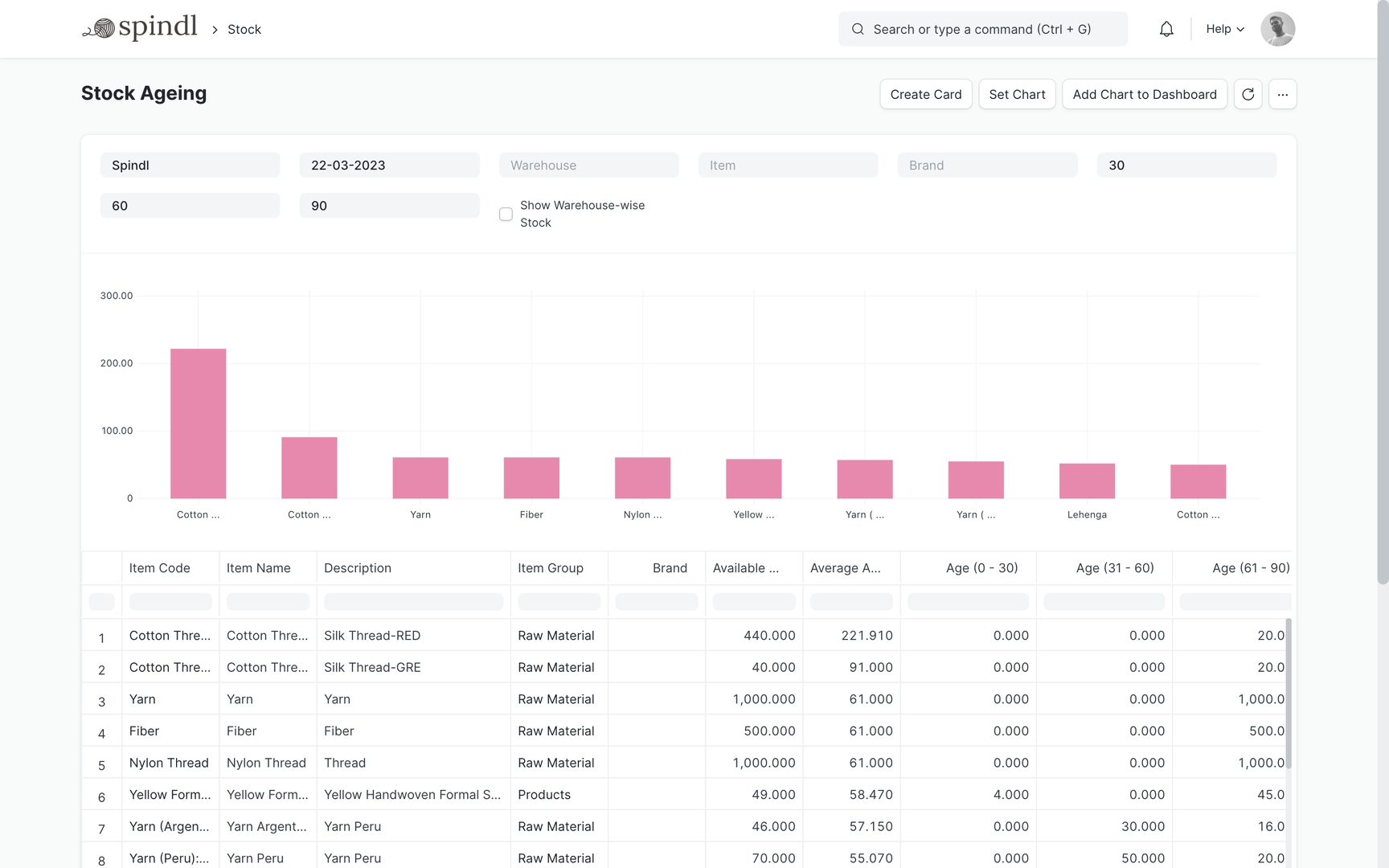

Stock aging and expiry

If there’s a lot of inventory lying in your warehouses, needless to say, that older items need to be cleared first. By using the Stock Ageing report, you’ll know exactly which items you should sell first.

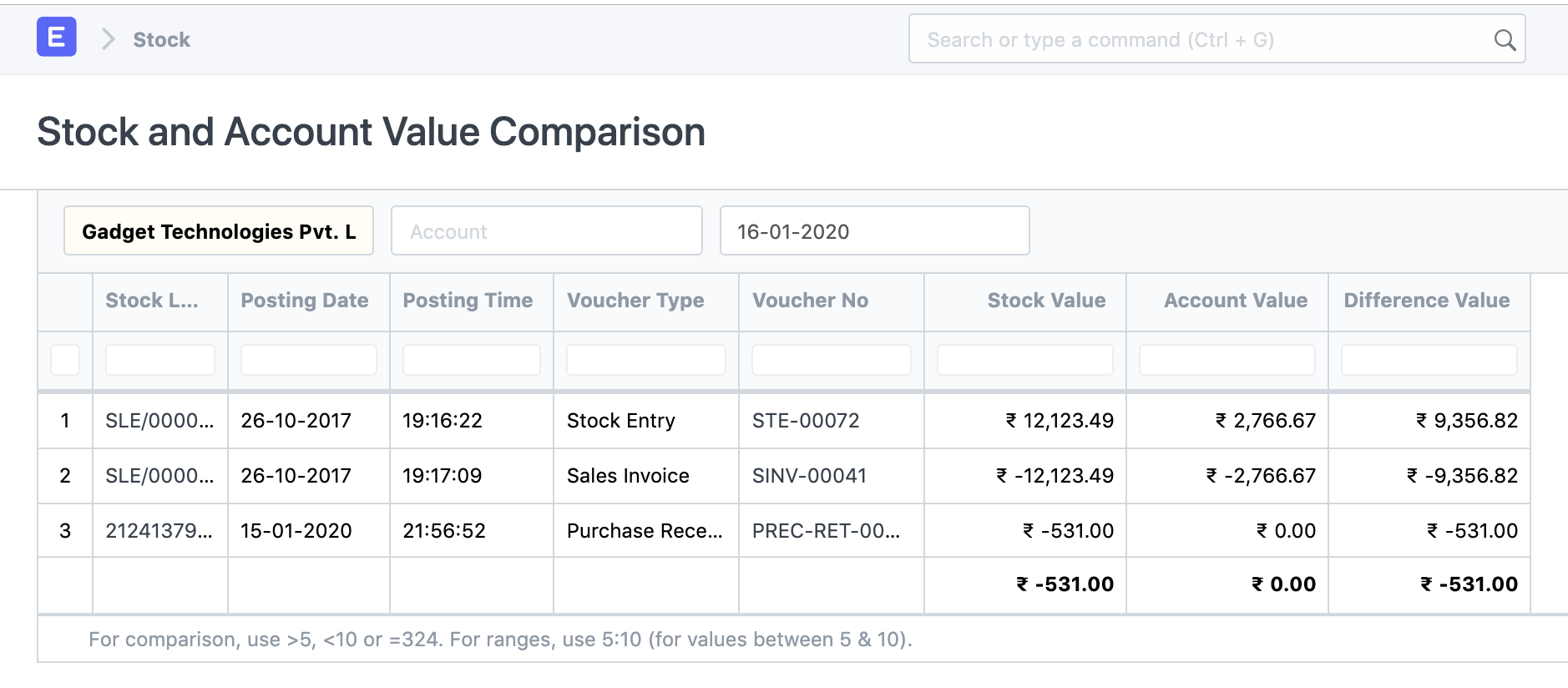

Stock and accounts comparison

At the end of the year when you’re closing your stock balance with a closing stock account, there can be mismatches in values. The Stock and Account value Comparison report helps you identify the errors so you can make corrections.

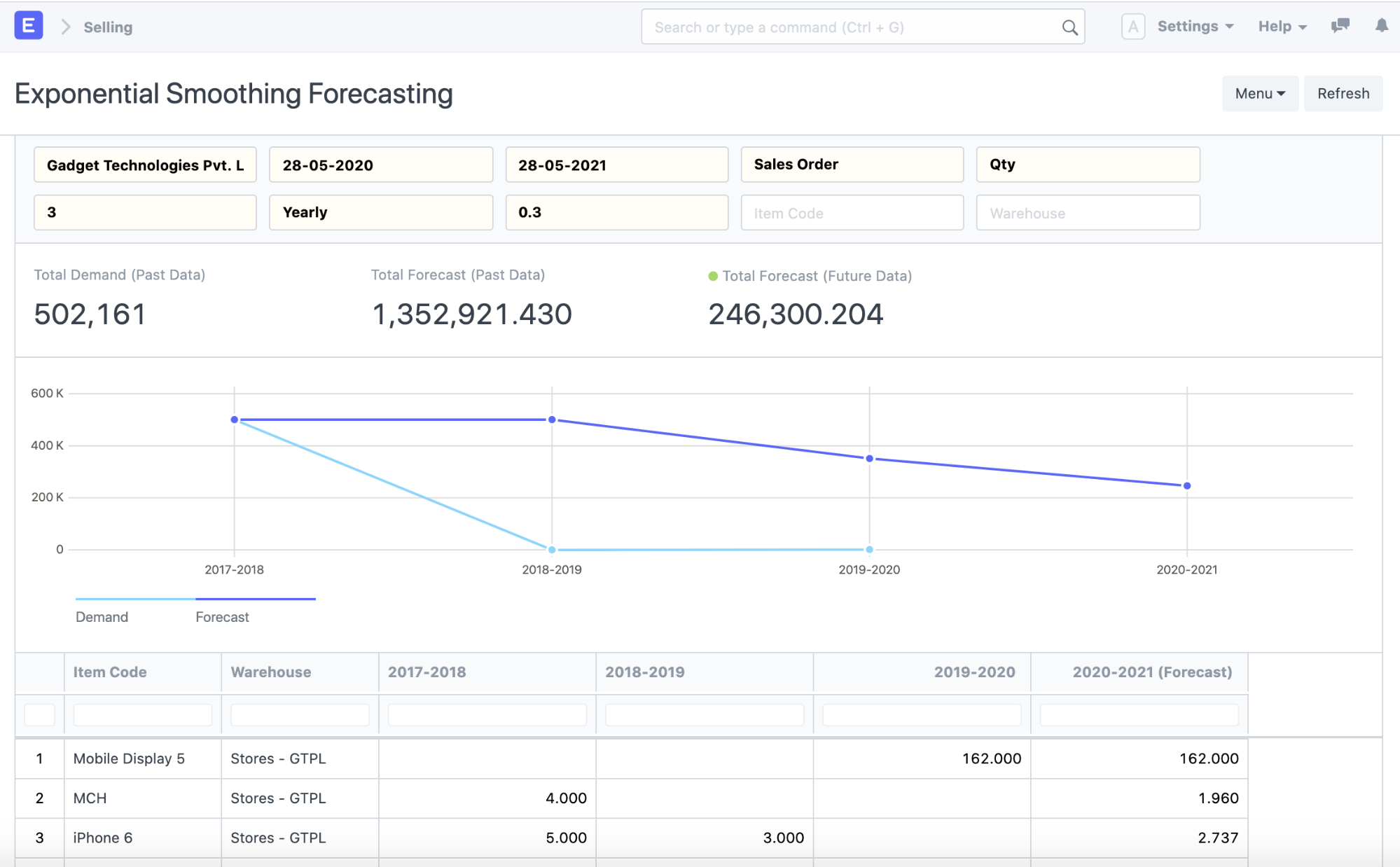

Demand forecasting

Based on previous sales data and exponential smoothing, demand forecasting in ERPNext allows you to see a forecast for next month's sales. Using this data, you can plan your inventory procurement and reordering.

Conclusion

Inventory management is crucial to run a successful retail, distribution, or manufacturing business. In the end, poorly managed inventory is as good as poorly managed financials, it leads to losses and wastage. On the contrary, a well managed inventory system will keep customers happy, boost sales, and hence revenue.

Prasad Ramesh

Marketing at Frappe.

Very well written blog. Curious to know if ERPNext has all the above listed features.