Backordering: The benefits, challenges, and how to do it?

Selling items with zero carrying costs is the dream. Backordering brings this close to reality.

Inventory is the key to any retail or eCommerce store. But some items cannot be stocked. With backordering you can sell such items without having them in your warehouses. Backordering comes with its benefits and challenges which we’ll explore in this article.

What is a backorder?

A backorder allows your customers to place orders with you which you cannot fulfill at that moment. The order cannot be fulfilled due to lack of inventory caused by the company’s procurement style or the items need to be manufactured. Consider it a backlog of orders.

A large number of backorders means that the demand is higher than the supply for the products. Higher number of backorders also results in long delays till the product reaches the customer. An item having a lot of backorders indicates its popularity.

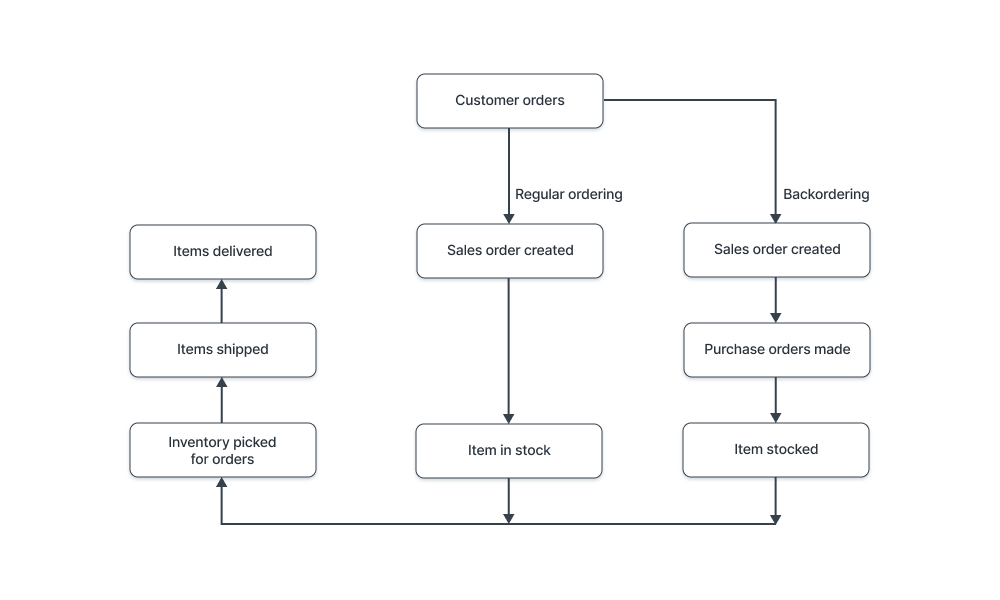

Here’s a flow diagram showing the difference between regular orders and backordering:

Why accept backorders?

Just because you currently don’t have the inventory doesn’t mean you shouldn’t accept orders. It’s a little tricky but if the product is good, customers wait and keep coming back. Many modern eCommerce stores put up items for ‘preorder’ while it’s still in production. Processing backorders has multiple benefits as we’ll see later. Backordering is a common practice in manufacturing companies that operate on make to order and companies that manage just in time inventory.

How a company handles it’s backordering also puts the inventory management to test. Few orders in the backlog and short turnaround times are good. On the other hand, a lot of backorders in the queue and long wait times for customers means that your inventory management isn’t efficient.

5 benefits of backordering

1. Save on storage space

Since you don’t hold a lot of inventory, except maybe a few items that sell consistently, you don’t need large warehouses.

2. Minimize carrying costs

When you hold inventory that doesn’t sell, you’re adding to carrying costs. With backordering, you only order/manufacture after getting the order so carrying costs are minimal.

3. Discount for customers

Between savings on warehouse rent and extra cash flow from avoiding wasted inventory (idle, dead stock), you save a good amount of money. When you save money, you can offer goods at discounted rates to your customers. Win-win.

4. Create hype for your product

If certain items are in such high demand that they’re regularly out of stock, customers would want them more. This creates a hype around a product making it desirable and loyal customers waiting to get their hands on it. An added benefit is product popularity via word of mouth.

5. Deliver custom products

Since you don’t hold inventory and the product shipments happen with a slight delay anyway, you can accept customization requests that you wouldn’t otherwise. A popular company that does this is Rolls Royce that builds bespoke custom cars. This was a luxurious example but a lot of industries offer customizations in products.

6 challenges in backordering

1. Carrying costs vs lot size

Since we already know what carrying costs are, let’s understand lot size. Lot size is the quantity of items procured or manufactured on a particular date to fulfil a customer order. Now, when practicing backordering, big lot sizes increase carrying costs. This is especially true if you’re manufacturing. Depending on your setup, it might be uneconomical to produce smaller lot sizes in one production run. This brings a conflict between choosing to pile up backorders or risking excess carrying costs. Solving such situations are specific to each business and best done by experienced manufacturing managers.

2. Lead time

Lead time is the time between placing an order with your supplier and the items reaching your location. If the items you need to fulfil your backorders have long lead times, it presents a challenge of piling up backorders and customer dissatisfaction. Again, to avoid such a situation, you have to risk increasing carrying costs by stocking items that have very long lead times (or even production times). Looking for local suppliers or paying more for faster delivery are alternatives.

3. Inventory management needs to be strong

As the stock is procured only after the orders are accepted, it’s easy to slip up between multiple customer orders and inventory levels. Hence, your inventory management should be tight enough to achieve short turnaround times.

4. Order cancellations

Accumulating a lot of backorders without an efficient fulfillment system leads to delays. Needless to say that long delays cause customers to become unhappy and cancel orders.

5. You may lose customers

Generally, customers are willing to wait longer for larger more complex products like machinery or designer furniture. But if they face constant delays and end up canceling their orders, they’ll switch to another provider.

6. Losing market share

It’s a cascading effect that starts from delays, order cancellations, then customers leave, and finally, you lose market share. Backordering done right has its benefits but there are certain risks involved.

Keep customers happy

Delayed orders pose a common problem for companies that run on backorders. Committing to a date and sending goods late is bad customer service. However, things happen in the real world and orders do get delayed. In such situations, it’s best to keep the customer in the loop with transparent communication. Send a sincere apology with some simple explanations as to why their order was delayed, most customers will understand.

Backorder or preorder?

They sound similar and you may think they’re the same, but they’re not! In preordering, orders are taken in mass, and products are shipped to all customers on a specified date range. In backordering, orders are taken and items are shipped as soon as possible to different customers at different dates.

How to create backorders in ERPNext?

One or two backordered items can be handled via spreadsheets. But, when there are tens or hundreds of items, you need software that’ll help track and manage all the orders, procure on time, etc.

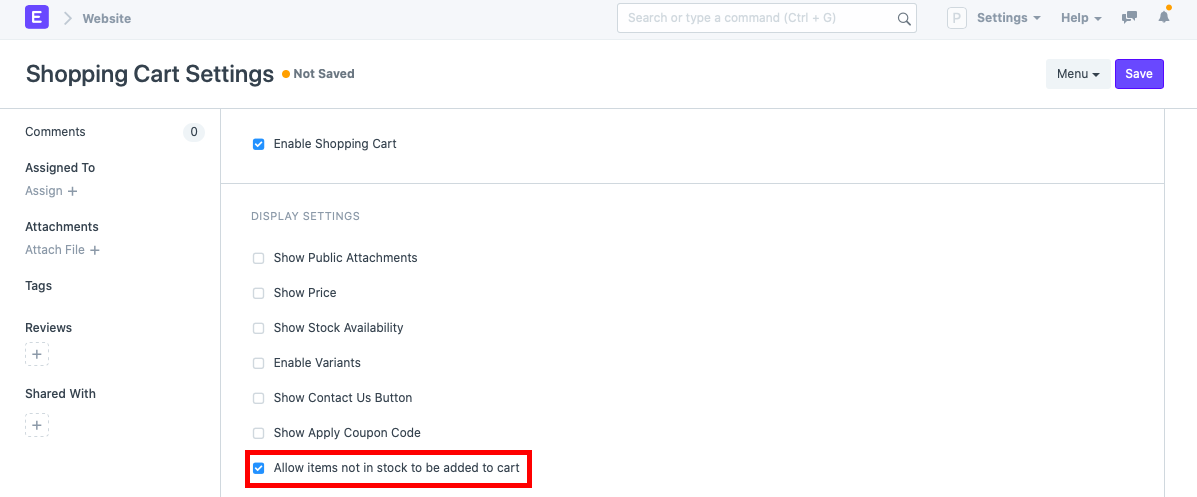

Configuring shopping cart

Any orders you may accept the old fashioned way via calls or emails, you need to enter in the ERPNext system. If you choose to display items online, you can configure the shopping cart to allow adding items even if there’s no stock in the warehouses. Now, your customers can add items to their cart which are not in stock. This will create a Sales Order in your ERPNext account, a ‘backorder’.

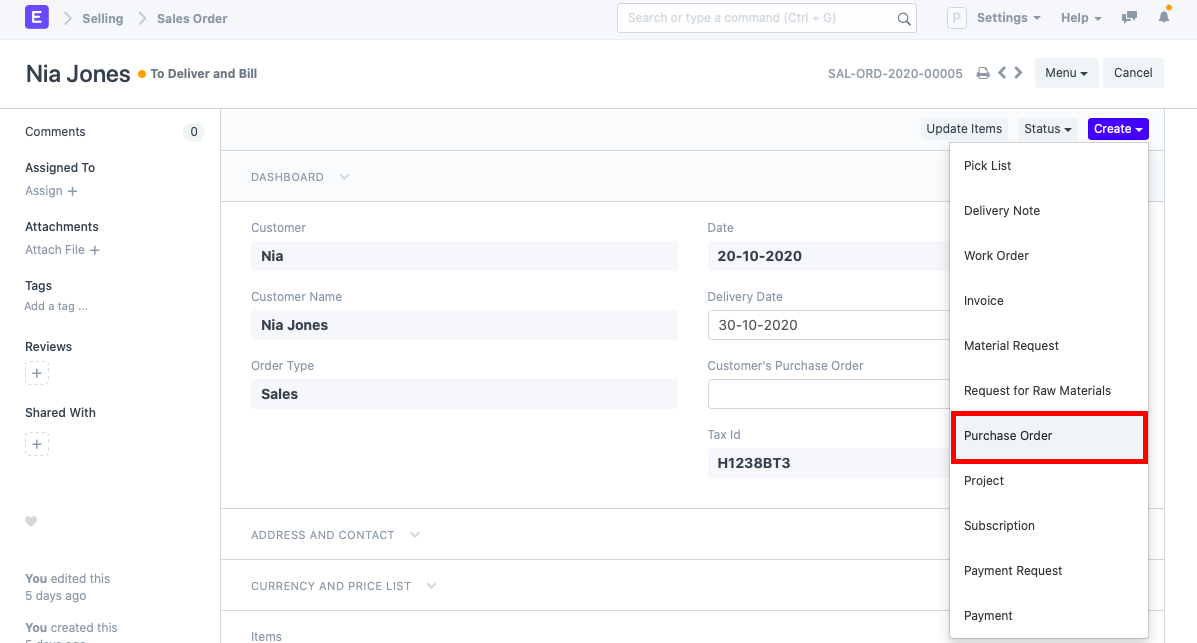

Create purchase orders from sales orders

Once you receive the sales order, you can create a purchase order to procure materials. If you manufacture those items, you can create a Work Order instead.

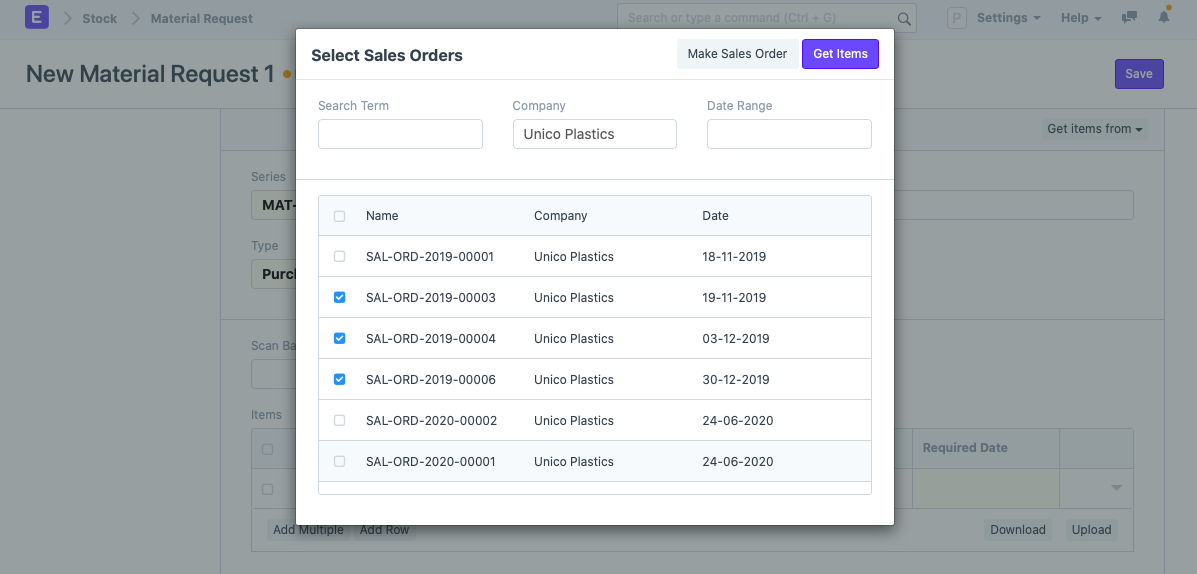

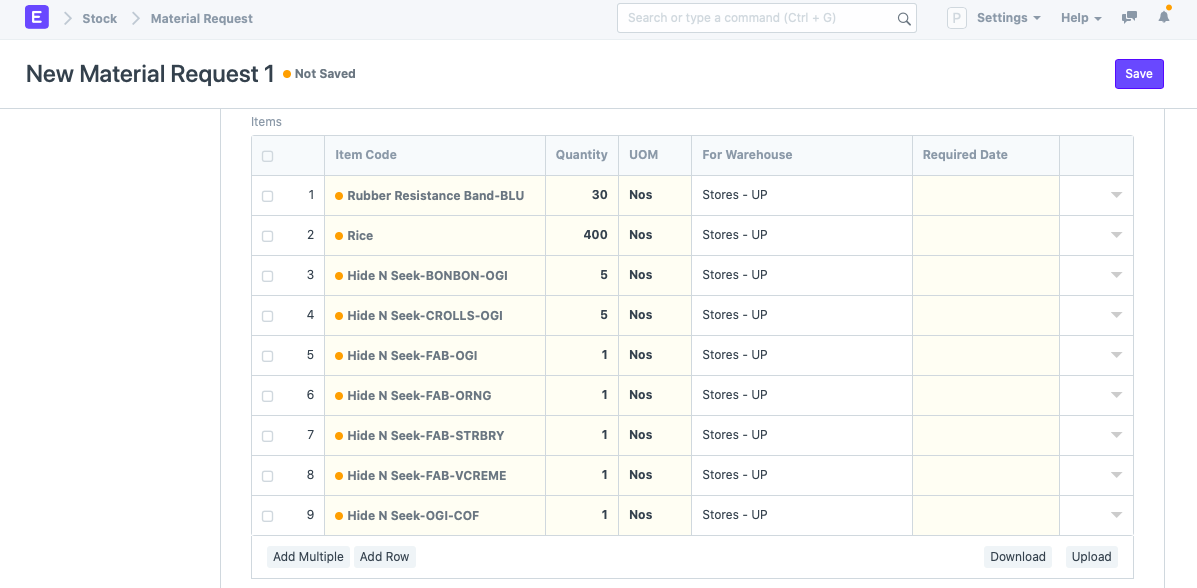

For procuring items in bulk from multiple sales orders, simply use a Material Request in ERPNext. This will allow you to select as many Sales Orders you want and fetch all the items listed in them like this:

You can see that items are fetched from multiple orders into the Material Request:

Checking stock balance

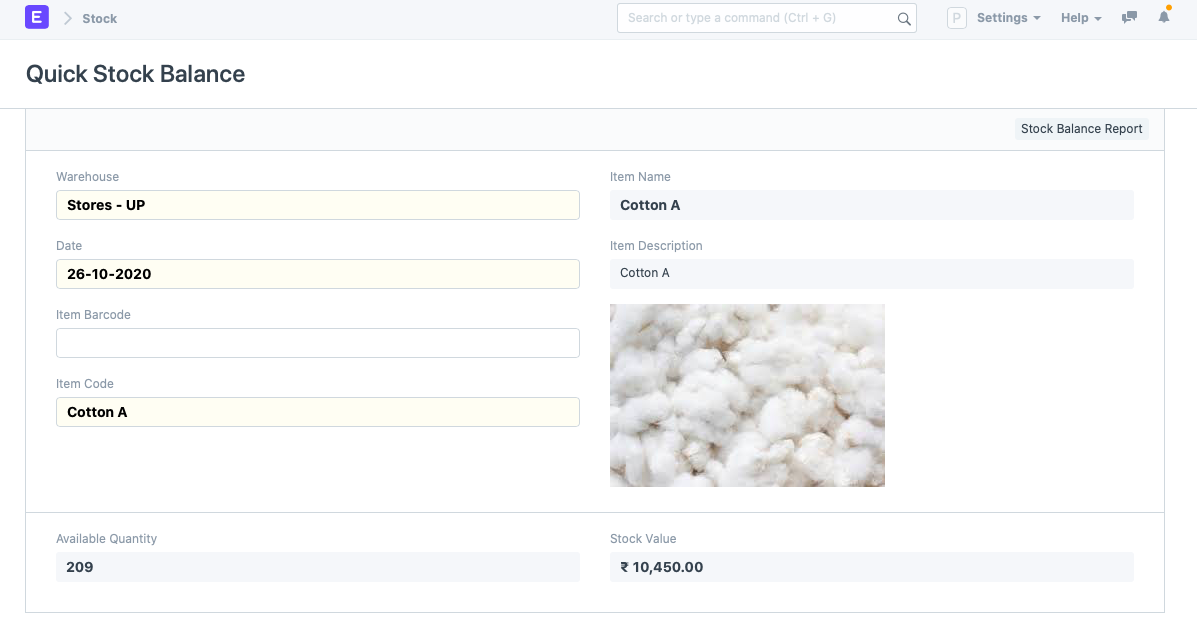

What if you want to quickly check the stock balance of certain items without having to browse through long reports? Not to mention that generating complex reports like Stock Balance is slightly time-consuming. Here, Quick Stock Balance comes in handy. Simply open it, enter the warehouse, date, and the item SKU. It’ll immediately show the available quantity in the selected warehouse along with its valuation.

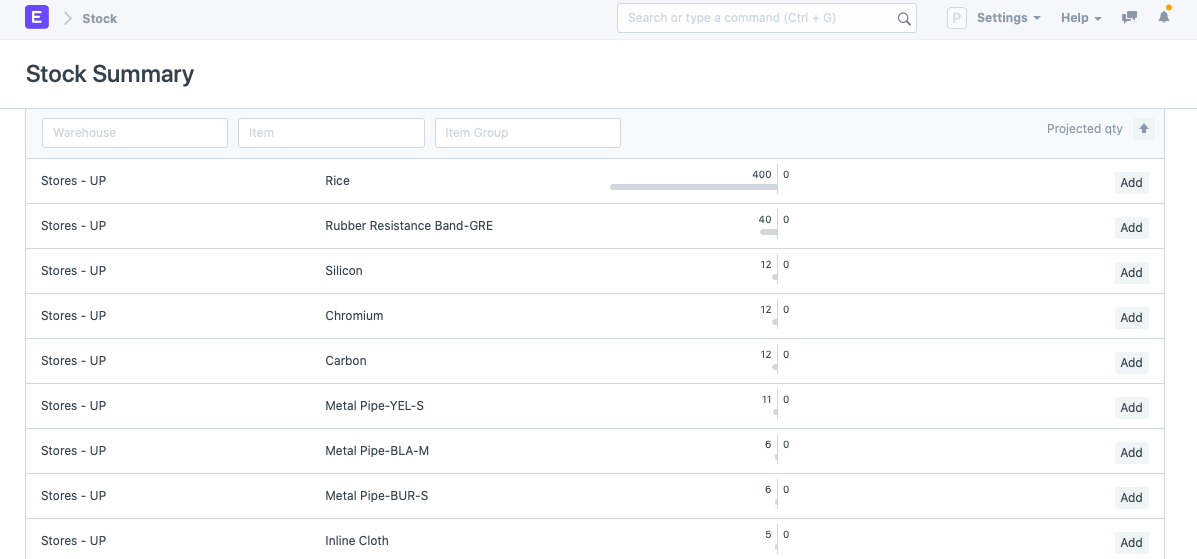

Alternatively, you can also open the Stock Summary report to see the reserved quantity (by orders) on the left and available quantity on the right:

The Stock Summary report gives a clear indication of the items that you need to procure to fulfill orders. The same data can be seen within individual items too.

Conclusion

You don’t have to lose out on sales just because you’re not holding inventory at the moment. Properly managed, backordering is an effective way to foster customers and keep your costs low. With good inventory management, timely deliveries, and proper communication, backordering is an effective way to sell with minimal carrying costs.

Prasad Ramesh

Marketing at Frappe.

tester2