Manufacturing basics explained with frequently asked questions

Understand manufacturing basics including the methods, types, and some FAQs

So your passion for building has led you to become a manufacturer and you want to get familiar with some manufacturing terms. Or you’re here just to know what phrases like job shop, material requisitions, production planning, etc, mean to keep up with your colleagues. Either way, in this blog, let’s get familiar with some manufacturing basics and answer some frequently asked manufacturing questions.

1. Some manufacturing lingo to get familiar with

Before we get into topics like BOM, materials, and inventory, let's get familiar with some commonly used manufacturing terms. These include subassemblies, job cards, subcontracting, and so on.

1.1 Subassembly

Think of subassmeblies like teams in a company, many units combined forms a larger unit. A subassembly is a group of parts that form another part. Subassemblies themselves can together form other subassemblies. It’s a parent-child relationship from the finished product to the subassemblies down to the individual parts. For example, consider that you’re manufacturing an office chair. Now you’ll use a cushion, cloth, and plastic to form a headrest, the headrest becomes a subassembly. Similarly, there are other subassemblies like back support, wheels, armrest, etc. These subassemblies are assembled to make the final product i.e., the office chair.

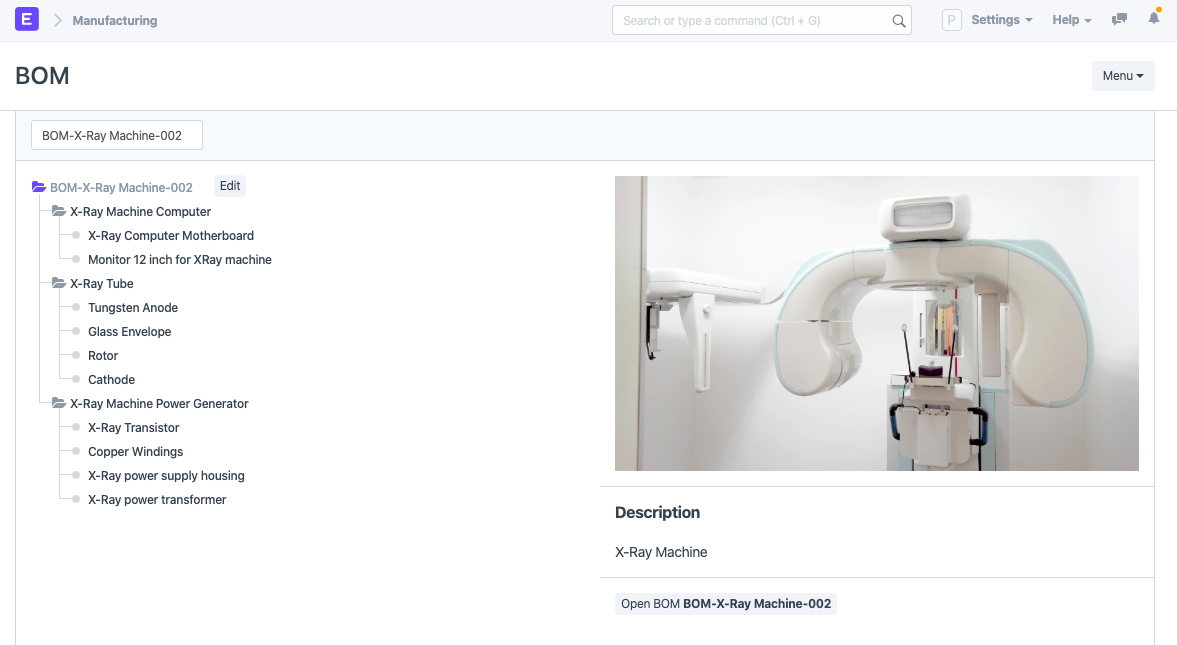

Let’s see a visual example. Here, the X-Ray machine is the finished product which has subassemblies that need to be put together first.

1.2 Job card

When a manufacturing order is being processed in the factory, activities are broken down into jobs and job cards are a way of recording the jobs done on the raw materials. Job cards are given to workers who handle different workstations. For example, there’s a manufacturing order for manufacturing 10 plastic pipes. The job cards will contain activities like ‘melting plastic raw material’, ‘pouring plastic in molds’, ‘finishing process’, etc. Each of these job cards will be given to different workers at different workstations.

1.3 Routing

A routing is a set of standard procedures raw materials go through to form subassemblies and finished products. For example, if you’re manufacturing a wooden chair, the routing would contain details about:

- Raw materials like wood sheet, polish, glue

- Operations like ‘measuring’, ‘cutting’, ‘gluing’, and ‘veneering’

1.4 Bottlenecks

Things don’t always go smoothly in a manufacturing line. Sometimes roadblocks occur that slow down the production of finished goods. A bottleneck is a point in the manufacturing line which slows down the entire line. Bottlenecks can happen due to various reasons like items arriving at machines faster than they can be processed, not having enough workers to process the materials at finishing. When a bottleneck occurs, items are waiting in line to be processed further.

1.5 Subcontracting

There are times when you can’t carry out all the manufacturing processing in your factory. In such cases, subcontracting is a good solution. When you contract other companies to carry out certain tasks of your manufacturing line, you subcontract the task to third party vendors, this is known as subcontracting. For example, you manufacture cars but for painting the components, you subcontract a vendor who paints the parts and sends them back for a fee.

1.6 CAD

If you’re manufacturing simpler products then designing could be done the old fashioned way using pencil and paper. More complex industrial designs can be made faster on CAD software. Short for computer-aided design, it’s the initial design of the product made by engineers or design experts using software. Using CAD diagrams is more common when the product to be manufactured is complicated involving a lot of parts.

1.7 Kitting

Kitting is the process of creating kits of different parts before shipping them to customers. For example, if a customer orders a personal computer, you may fulfill the order by choosing different brands of CPU, keyboard, mouse, monitor, etc. When an order arrives, different items are pulled from inventory, packaged together, and shipped to fulfill the order. Kitting saves time by combining purchase orders and the logistics of shipping items in different packages.

1.8 Industry 4.0

The fourth industrial revolution has to do with automation and using smart machines to enhance manufacturing lines. The use of IoT devices, connected machines, smart robots that detect anomalies are all a part of Industry 4.0.

2. What are the methods of manufacturing?

Now that you’re familiar with some common manufacturing terms, let’s see the differences between manufacturing methods.

2.1 Make to stock

In make to stock, products are mass-produced and stored in warehouses. It’s the most common type of manufacturing method where the produced stock is either sent out to distributors or sold to customers (other businesses) regularly. For example, fast-moving consumer goods (FMCG) products, clothes, furniture, etc. A standard bill of materials (BOM) is used as a recipe to manufacture items and certain inventory levels are maintained. Hence the phrase ‘make to stock’. The stock to be manufactured in advance is generally projected based on demand forecasting.

2.2 Make to order

In this method, items are manufactured only when the company receives an order. Make to order is common in high value or specialized items where there is no large consumer market and selling products takes a long time. For example, specialized machinery equipment and their parts or large vehicles like planes and ships. However, the BOM usually remains the same for one product. Since the manufacturing happens only when a sales order is received it’s called ‘make to order’.

2.3 Engineer to order

This goes one step further where the item is produced based on custom requirements specified by the buyer, which leads to each product being unique. Usually, these items are not mass-produced, for example, furniture or machinery with custom dimensions or materials. For each order, the specifications are different and a different BOM is created, hence engineer to order.

3. What are the types of manufacturing?

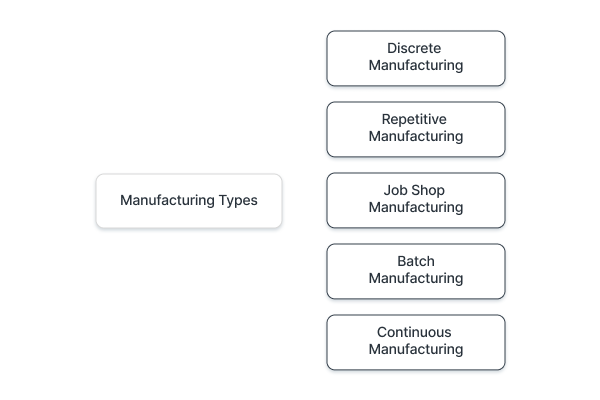

Depending on the industry, there are five different types of manufacturing practiced as outlined in the following diagram.

3.1 Repetitive manufacturing

Repetitive manufacturing is the production of the same item over and over again. Raw materials and operations tend to be the same in repetitive manufacturing. Since the same items are produced over longer periods, the lead times are often short. Examples include electronics like smartphones, speakers, automobiles, etc.

3.2 Discrete manufacturing

The manufacturing of different or distinct items is known as discrete manufacturing. In discrete manufacturing, each type of item will have its own bill of materials. Each final product is a separate unit that can be packed and moved. For example, 10 distinct units of laptops.

Discrete manufacturing industries include different types of cars, furniture, phones, and even planes.

3.3 Job shop

A job shop is a small company that performs specialized manufacturing jobs and processes. Job shops deal with customizations and bespoke products. Small to medium-sized orders are fulfilled in batches at a job shop. Job shops usually contain different types of machines nearby and hence can carry out various operations on materials fast. They’re useful for subcontracting during ‘engineer to order’ and saving time on your production line.

3.4 Process manufacturing

Process manufacturing is about producing items in bulk that are not distinct from one another. For example, consider paint, you cannot distinguish between individual paint units like you can with brushes. Items are measured by weights or volumes in process manufacturing. There is no bill of materials, instead, recipes/formulas are used to process raw materials and reach the final product. For example, 100L of paint.

Industries that manufacture food, beverages, pharmaceuticals, cosmetics, paints, etc., follow process manufacturing. Within process manufacturing, there are two types depending on whether the products are manufactured in batches.

3.4.1 Batch manufacturing

In batch manufacturing, products are produced in batches with a batch number associated with a group. A batch goes through a series of processes before being finished and stored in inventory. Common industries that apply batch manufacturing are pharmaceuticals, fast-moving consumer goods (FMCG) like chips and biscuits, cosmetics, etc. Batch numbers help group location of production, doing product recalls in case there are defects, and group expiry dates.

3.4.2 Continuous manufacturing

This is the opposite of batch manufacturing where items are produced continuously without interruption. Examples include industries that process fluids or other items that don’t need pauses. Continuous manufacturing can be practiced when the chances of your product going bad or defective are minimal and hence no chance of product recalls or need for batching.

4. Frequently asked questions in manufacturing

4.1 What is BOM

A bill of materials is a list of raw materials, subassemblies, and other things required to fulfill an order. Consider a simple example of a T-shirt, to create one you’d need yarn, threads, buttons, and some operations like cutting, stitching, and packing. Additionally, you’d also need different workstations that take care of cutting, stitching, and packing. To operate these workstations, you need workers. All such details and more are captured in a BOM.

A BOM is the backbone of your manufacturing line and hence should be created carefully with correct details.

4.2 What is work order/manufacturing order

A manufacturing order or work order contains details about the products to be manufactured under a specific timeline. You may receive multiple orders from different customers. Work orders can also be created on a timely basis in make to stock or be a result of a material request/requisitions form. Generally, manufacturers group similar items for production and create work orders to produce them in bulk.

4.3 What is the shop floor

A shop floor is the actual production environment where the items are processed and manufactured. The shop floor houses all the equipment and workers, it’s where the actual production happens; like a factory.

4.4 What is production planning

As a manufacturer, you’ll have multiple customers and those customers will place multiple orders with you. Now the task of planning the production of various products is in your hands. When performing production planning, various factors are taken into consideration like available raw materials, procuring more if needed, workstation availability, customer order due date, etc.

4.5 What is a material requisition

Before planning to produce items on the shop floor, you need to ensure that there are enough raw materials to go through with the production. In case there is a shortage, materials requisitions are created to procure more raw materials. They’re also made to maintain a minimum quantity of finished goods in warehouses.

4.6 What is agile manufacturing

Agile manufacturing is an approach to combat changing conditions in the manufacturing cycle via iterative process and flexibility. An agile approach to manufacturing is being taken by companies due to the rapidly changing manufacturing landscape and constant technological improvements. In agile, actions are taken as a reactive measure to the changing factors.

4.7 What is lean manufacturing

Lean manufacturing is about reducing wastes and making the manufacturing process as efficient as possible. Lean principles and lean tools are used to achieve the goals of lean. They focus on reducing wastes, standardizing work, minimizing variance, etc. Although they have similar goals, lean is a very different approach from agile manufacturing. In lean, actions are taken proactively to make processes more efficient.

4.8 What is an OEM

Short for original equipment manufacturer, it is the original company that manufactured the products which may be sold by other companies under different brands and packaging. Goods manufactured by OEMs may also be used as parts by other companies in the products they sell. A common example is the Android operating system, here, Google is the OEM and Samsung adds it’s own customizations to the OS before shipping it in Samsung phones.

4.9 What is six sigma

Six sigma is a set of techniques for improving processes by removing defects and minimizing variability. There are six levels and a process is called 6σ when 99.99966% of all the items produced are free of defects. Six Sigma uses statistical and quality management methods.

4.10 What is smart manufacturing

It’s a category where smart machines, automation, and sensors are leveraged to enhance a traditional manufacturing line. Smart manufacturing and smart factories is a term that comes up often along with Industry 4.0. Other concepts like advanced robots with autonomous communications, processing big data for demand prediction, 3D printing for prototyping, and iterative design are all a part of smart manufacturing.

4.11 What is designing for manufacturability

Designing for manufacturability (DFM) is about designing your product such that it can be manufactured easily in production. Often, in the prototyping phase, products are designed on CAD systems then samples are made with quick iterations. Not considering the practicality of manufacturing the product at scale lead to slowdowns or even losses. DFM is a way to plan such that the product can be manufactured continuously at scale. Factors like manufacturing process, design, raw material availability are at play in DFM.

4.12 What is manufacturing overhead

Manufacturing overheads are indirect costs incurred by a company. These are costs that occur other than direct costs of raw materials and labor. Examples of manufacturing overhead include staff other than workers like supervisors, electricity or fuel, equipment maintenance costs, etc.

5. Before and after manufacturing

Manufacturing is only a part of a larger cycle called supply chain management. To produce your products you need to source raw materials from suppliers and sell your products to customers. You need ways of reaching them and have records of communications. This whole process of procurement to manufacturing to delivery is known as supply chain management. Maintaining relationships with both suppliers and customers is a necessity for the success of your manufacturing business.

Depending on the company size, there are also dedicated sales and marketing teams that help generate more revenue. After selling, there’s customer support in case there are any issues or queries about your product/service.

Conclusion

First, we got familiar with some manufacturing terms, then we talked about the three different manufacturing methods, and then we talked about the manufacturing types. After this basic introduction, we answered some common questions in manufacturing.

I hope this blog answered your questions about some common manufacturing terms, types, and methods. Did you find this useful?

Prasad Ramesh

Marketing at Frappe.

@roman Schnwyzer ERPNEXT support SRM. Infact you can customize ERPNext as you like.

Thank you for the article. May I ask you if ERPNext supports Supplier Relationship Management?