What is a blanket order and should you do it for your business?

Blanket orders are a win-win as they’re beneficial for both suppliers and customers. Let's learn more and see if you should do it.

When the material demand in your floor or business is predictable and constant, using blanket order agreements results in a lot of savings while ensuring a steady supply. Let’s see what they’re all about.

What is blanket ordering?

A blanket order is an arrangement between a buyer and a supplier where the goods to be delivered, price, and dates are fixed as per agreed upon terms. Blanket orders are an easy way to order goods from a supplier. It's good for both the customer and the supplier since it has advantages for both parties.

The key to make the most out of blanket orders is to make sure that buyers know what items you need, the number of items needed, and when you need them so that the suppliers can plan accordingly. For example, if your company needs 25 cases of tissues per month on a monthly basis then communicate clearly with the suppliers so that they have enough time to produce the required quantities before your next shipment.

When should you blanket order?

Blanket orders work best when you have constant material consumption in fixed quantities in fixed time slots. For example, if you constantly manufacture 300 steel pipes every month, you know that you’ll need 3,000kg of iron, 60kg of carbon, and so on.

Blanket orders can be applied to all levels of production, from a single-product contract to an order covering a product line or even the entire inventory of an organization. This allows you to buy in bulk without running out as often, which saves time and money while giving your company more control over its inventories.

Advantages of blanket orders

Now, let's get into the benefits of blanket orders.

There are many benefits to blanket orders like the ability to buy in bulk without running out as often, time and money saved while giving your company more control over its inventories, and so on. Let’s see what they are.

Reduces costs

Buying in large quantities allows the benefit of bulk pricing. Say if you order 12 tons of iron and even if the deliveries are made every month or so (they usually are), you’ll get discounted prices for giving a buying commitment.

Blanket orders can be used for all materials used in the company across all production lines. Instead of buying in a huge lot and storing, blanket orders allow timed deliveries. This means that you don't need to store inventory and allocate extra storage space. As a result, you also save on extra real estate costs.

If you're a distributor, blanket orders are ideal for you as they save a lot when you purchase and sell in volumes.

Shortens lead times

As you don't have to search for new suppliers and choose one each time you need raw materials, the result is shorter lead times. The result is better and prompt service for your customers. One thing to note is that you should also pre negotiate lead times with your supplier before agreeing to a blanket order.

Saves a lot of time

The time savings are also multi fold. The procurement department’s time is saved since they don’t have to search and vet new suppliers each time there’s a new production cycle and more raw materials are required. With blanket orders, there’s only one contract, one negotiation for a year or more instead of 20 or 50. Even in your inventory or ERP software, instead of wasting time in creating multiple purchase orders, you can create one blanket order.

Advantages for suppliers

Blanket orders also bring advantages to suppliers like a fixed revenue stream. If a supplier cuts deals with multiple buyers for multiple blanket orders, their revenue stream becomes very stable and they can focus on procuring and delivering instead of finding new buyers.

Challenges in managing blanket orders

Coming to the challenges, there are a few things to consider before setting up blanket purchase orders in your company. There are a few logistical and operational hurdles to overcome before you can reap the benefits of blanket orders.

Accurate forecasting

Forecasting the required materials accurately is key to make blanket orders work efficiently. This process is quite error prone in the initial months of your production cycle since you don’t have enough data to forecast needs. In addition, if you forecast a quantity but the market demand changes due to seasonal factors, you’ll still be left with extra stock. If you’re unsure about demands and don’t have a procurement manager or MRP software, you might want to wait before doing blanket orders.

For example, if you manufacture steel pipes and you know that demands are high in monsoon and low in winter, you should set the terms of your blanket order accordingly.

Adds accounting overhead

Since blanket orders contain a lot of items for a long period of time tied to a single document, it’ll be difficult for the accounting department to find and log them properly. Auditing and closing the books also takes more time since accounting will have to log the accurate number of items purchased and returns if any.

Matching orders to invoices

A blanket purchase order is one document but you will receive multiple sales invoices from your supplier against the multiple deliveries they make. Matching them to keep track of transactions, deliveries, and books can be challenging if your software doesn’t support this.

Requires software for handling

All in all, it’s clear that you need software to keep track of blanket orders. Pen and paper, excel sheets, and simple accounting software just won’t do. So it’s an additional investment but at scale, using blanket orders will save a lot of time.

Challenges for suppliers

If a buyer agrees to a certain amount but is unable to utilize the stock or wants less now and more later, such situations will leave the supplier with extra stock and cause a burden. Making a tight contract or setting clear expectations can minimize this risk.

Well beforehand, discuss with your buyer how much quantity will be required at what intervals. Also, discuss terms for unused materials so you can sell what will not be required.

Best practices in blanket ordering

Now, let's look at the list of best practices to do when opting for blanket orders. These will help you ensure that you're getting the most out of blanket orders.

- Start with a purchase order approval process, you want multiple stakeholders to be involved in this decision since any oversight will cost the company.

- Perform ongoing monitoring on what is in stock and what needs to be replenished to account for any changes either way.

- Make sure you keep an eye on the lead time required for each item in your inventory

- Have suppliers ship via ground delivery as opposed to air when possible to save on shipping costs. This will work in blanket orders since the delivery dates are fixed.

- You should also make it clear at the beginning how many pieces per size or color need to be delivered if they're not all available at once. This will ensure you have the right materials or alternatives if the first choice is unavailable.

- Negotiate a minimum order quantity with your suppliers (ensure that they have enough room to be able to provide you with goods).

- Find out what product options are available, get quotations, and take into account delivery times.

More about blanket orders

Now let’s take a look at a few more things like examples of blanket orders, and differences between terms commonly used with blanket orders.

What to include in a blanket order agreement?

For safety on both sides of the blanket and fostering a long term relationship between the buyer and supplier, these things are a must include in blanket orders:

- Pricing

- Duration of agreement

- Intervals of delivery

- Mode of delivery

- Location to be delivered

- Payment terms

- Item quality standards

- Item quantity

- Item variants

- Terms of contract violation and cancellation

- Terms for returns if any

- Terms for when the supplier can sell unused items

When you implement a blanket order, it is important to also set an agreement on how often the supplier will be paid for their products. The payment frequency can be paying for a product in full upon delivery (to get the cash flow going). Or only partial payments after each shipment has been delivered and before new orders are made. Both of these options have benefits, but one option may work better depending on your situation.

Blanket order example

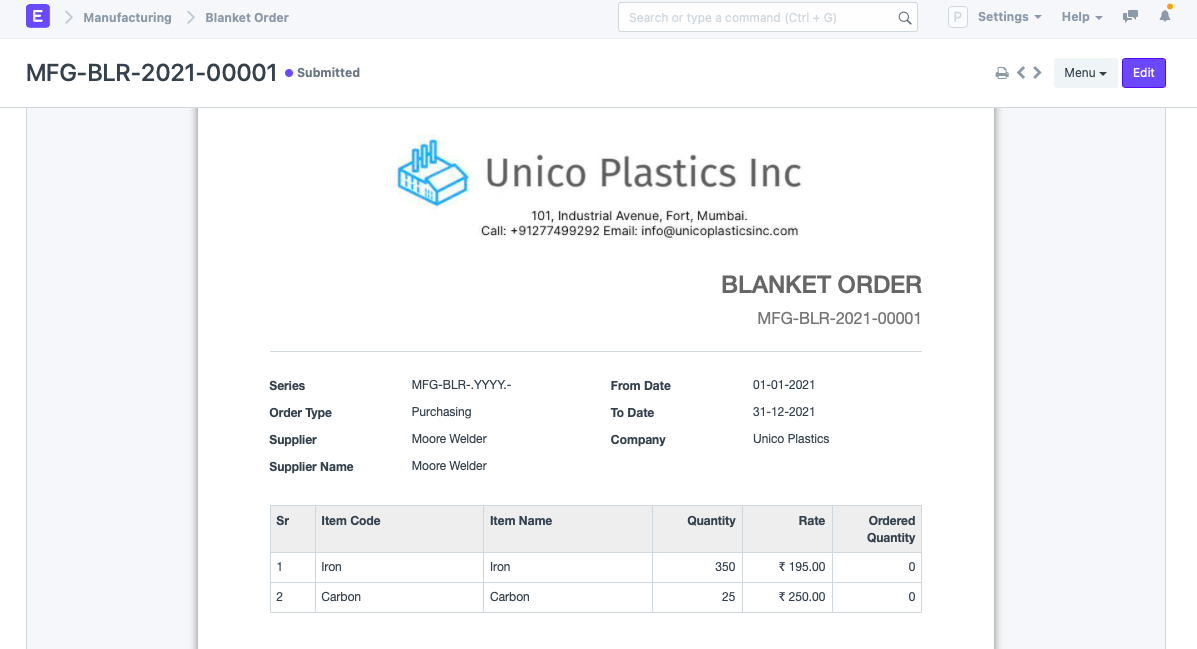

Here’s an example of a blanket order created in ERPNext:

Blanket order vs bulk order

You must've also heard the term bulk orders often but they're different from blanket orders. The difference is that bulk orders are done only once to procure a large quantity of inventory whereas blanket orders are a running agreement where the bulk of items are delivered in weekly or monthly intervals.

Should you do blanket order

Blanket orders are beneficial for both suppliers and customers. Let's learn more and see if you should do it. Blanket orders are most effective when:

- You have limited storage space and don’t want to stock a huge bulk of inventory

- Same quantities of goods are needed within a specific time period

- Trustworthy suppliers can be identified who can fulfill deliveries on time

- Bulk discounts apply or the cost of individual items go down

- Timely deliveries reduce storage costs and risks

Creating blanket orders in ERPNext

Now let’s see how ERPNext can help you manage blanket orders. You can manage both sales and purchase blanket orders in ERPNext. This means both suppliers and customers can manage their blanket order records in ERPNext.

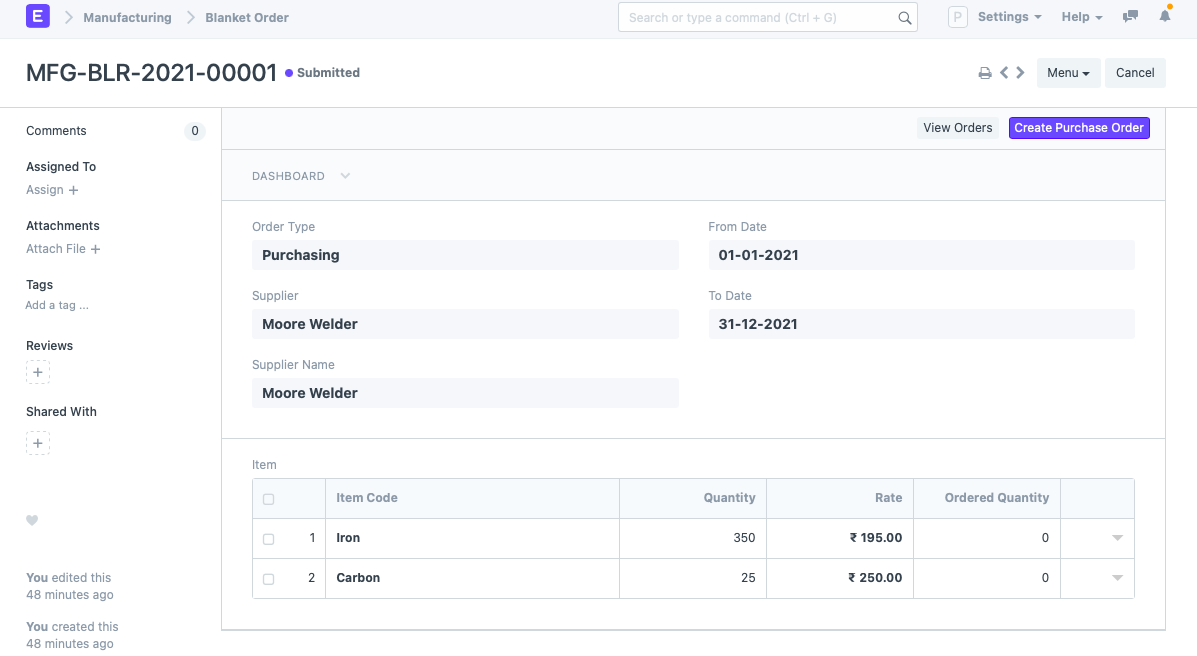

Simply go to the Blanket Order list and create one. In the new blanket order, select the supplier, date interval, and items. Enter the number of items and the rate at which the pricing was negotiated. From here, you can create a purchase order needed as per your requirements.

If you scroll down a bit in the Blanket Order, you’ll see a section for Terms and Conditions, here you can add the agreement terms of your blanket order. You can also create a standard template and make changes per supplier/customer as needed.

Conclusion

In the end, both parties are winners when it comes to blanket orders. For suppliers, it means they have guaranteed sales, which in turn provides a stable income. This is especially helpful for small businesses that rely on one or two key clients for the bulk of their business. For customers, it provides them with greater control over costs and inventory levels, so they don't need to worry about reordering products as often (saving them time and money).

Prasad Ramesh

Marketing at Frappe.

This is very informative article as a blanket buyer i can save my time, i will give you 100% marks for your great effort. we are also providing these type of services. wholesale blankets.