What is putaway strategy and how is it done in warehouses?

Putaway is a warehouse management strategy used to make efficient use of space and store items properly

Three times a week, drums and boxes of inventory fly in among the 20 warehouses managed by Noah, the regional Warehouse manager. Between stocktaking, quality checks, and other activities, he barely has time to coordinate locations for inventory when it arrives. With the growing inventory flow, he knows this can’t be ignored any further. The warehouses have started looking messy and become a bottleneck for production.

In many growing warehouses, warehouse managers or supervisors like Noah follow simple rules to route inventory to the different warehouses. These are called “putaway” rules, or just putaway. As your inventory levels grow, putaway plays a vital role in managing inventory space and helping ensure a steady supply of materials to your production line or packing station.

Using the right putaway strategy and software saves time and efficiently manages space in busy warehouses like it did for Noah, our fictional warehouse manager.

What is putaway in warehouse management?

Putaway is a rule-based system of moving items from a received shipment to the right places in warehouses. This ensures that goods are stored at the right locations based on their storage condition requirements. A key benefit of using putaway is easy access to goods and organized inventory.

How is putaway done in warehouses?

At one of the warehouses, the company’s procurement manager, Elsa does stock checks and places orders to replenish stock levels. When the order arrives, the items are unloaded from the trucks by warehouse workers. Let’s say there were 10 trucks, tons of materials, and different varieties among them. The workers use hands and forklifts.

But wait a minute. How would Noah and Elsa decide where to store the items once they’ve arrived? After all, there are so many varieties, sizes, and weights.

This is where putaway comes into the picture and it’s done using one of the following strategies.

What are the types of putaway strategies?

Elsa talks to the warehouse supervisor Noah and they list down all the putaway strategies. They found four well known putaway strategies used to move goods into warehouses.

But first, let’s understand some criteria that decide which putaway strategy is used when. After all, you need to know the fundamental criteria behind these strategies. Each putaway strategy has its own place. Let’s say Elsa and Noah consider the following deciding criteria before choosing putaway strategies:

- Based on space availability

- Warehouse size

- Number of warehouses at location

- Quantity of items being received

- Based on item

- Variety of materials in the warehouse

- Storage conditions of the materials

- Physical weight of materials

Keeping these criteria in mind, let’s look at the different types of putaway strategies.

Putaway strategies based on space availability

Depending on criteria 1, i.e., whether items had to be putaway to final locations immediately or later, there are two categorizations. Now, Noah handles huge warehouses with floor markings and the incoming inventory drums are supposed to be stored at these markings. The smaller items are stored in racks and bins.

Direct putaway

For smaller items, he uses direct putaway which means that on receiving the items in trucks, the workers load it down and immediately send it to an available/assigned warehouse space. To get this done properly, Noah checks ERPNext and determines available warehouse spaces. In this case, since there’s no temporary storage location where everything is stored and items are directly sent to warehouse locations, it’s called direct putaway.

Direct putaway is practiced when:

- The warehouse sizes are relatively small

- There are fewer locations

- Less variety in materials

Direct works in such conditions since in smaller warehouses and fewer locations, the traveling distance between loading dock and final location is small. This also means there’s less chance of human error. It’s also easier to locate bins and shelves to putaway the items.

Indirect or combined putaway

Now for the large drums to be placed over floor markings, indirect putaway is used. When the large drums arrive at the loading station, they’re loaded down with forklifts and stored at a temporary area.

After finding ideal spots for these drums with the help of ERPNext, Noah instructs the workers to move the drums to marked locations. Since each drum is huge, around 15 feet, they are putaway to floor markings and not racks or bins.

Elsa and Noah had a chat with the manufacturing department and they decided on how the drums should be placed. They wanted the drums to take available spaces sequentially as they come. Then they’d be consumed in a FIFO manner.

The reasons for using indirect putaway can be:

- Huge warehouses mean it’s hard to locate where to putaway

- The same problem exists with having a large number of warehouses

- Large variety and volume of items received also presents a challenge to putaway items directly

For example, the following week, if a shipment arrives with 10 different items, 15 containers of each, and Noah handles 20 warehouses each of which is 30,000 sq feet it’s impractical to use direct putaway.

Here, using indirect putaway gives more control and precision when sending items to their correct locations in warehouses. Usually, it's done in huge warehouses. The main challenge being the difficulty in locating where to put away received goods.

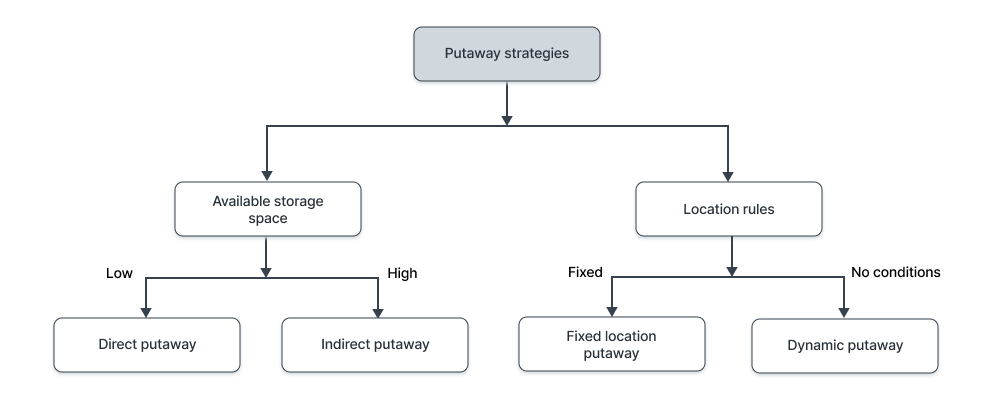

Here’s a diagram that shows how to decide putaway strategy:

Putaway strategies based on item

Whether or not having a fixed location for specific items also brings us to two different categorizations in putaway strategies.

Fixed location putaway

In fixed location putaway, a particular location is permanent for a group of items. Noah decides that warehouses 1 to 10 are reserved for heavy items. He assigns the other 10 warehouses for items that require cold storage, lightweight items, and so on.

Now, in one of the first 10 warehouses dedicated to heavy items, Noah arranged for 20 floor markings A, B, C,...T. There may be other small areas in the warehouse where lighter items are stored and even have racks and bins. But let’s ignore that for the sake of simplicity and focus on the area for heavy items.

Whenever heavy drums arrive, it’s fixed that they’ll go to one of the warehouses among 1 to 10 and in one of the markings between A to T. This way, Noah ensures that goods are always easily accessible.

In fixed location putaway, since the location is fixed, the key advantage is less chance of confusion.

Dynamic location putaway

In the above strategies, a priority or logic is set. Based on that, items are sent to different locations.

Now, in dynamic putaway, the location is not fixed. The items are putaway in any available space where they can fit. It can be untidy but saves space. On the other hand, it can be a nightmare if this is practiced in large warehouses without proper records of what went where.

In some warehouses, robots and efficient labor is used to quickly retrieve items. Dynamic putaway is a common practice in eCommerce stores since it saves time and space.

The role of software for making putaway a success

As seen above, the goal of putaway is finding a suitable and empty warehouse space. As you may have guessed, doing this with spreadsheets is inefficient. That is why software with putaway features are used in large warehouses to manage it efficiently. Using software for putaway enables warehouse supervisors like Noah to focus on more important things like quality checks instead of communicating with workers to find empty spots for storage.

How did this feature come into ERPNext

Keeping the above points in mind, Marica, a software engineer made the Putaway Rule feature in ERPNext. In my conversation with her, she explained the problems Putaway Rule solves and her approach to keeping it flexible.

The most prominent problem Putaway Rule solves is managing warehouse capacity. In busy warehouses where items are bought and transferred regularly, having a system to see and manage capacity becomes crucial.

The Putaway Rule keeps consistent with the flexibility of ERPNext. Within a Purchase Receipt or Stock Entry, vacant warehouses are automatically shown on activating this feature or saving the document. Putaway is quite flexible in ERPNext since it allows control at the transaction level.

Creating putaway rules for warehouse management in ERPNext

Now, let me show you how to manage putaway with ERPNext and also show its flexibility.

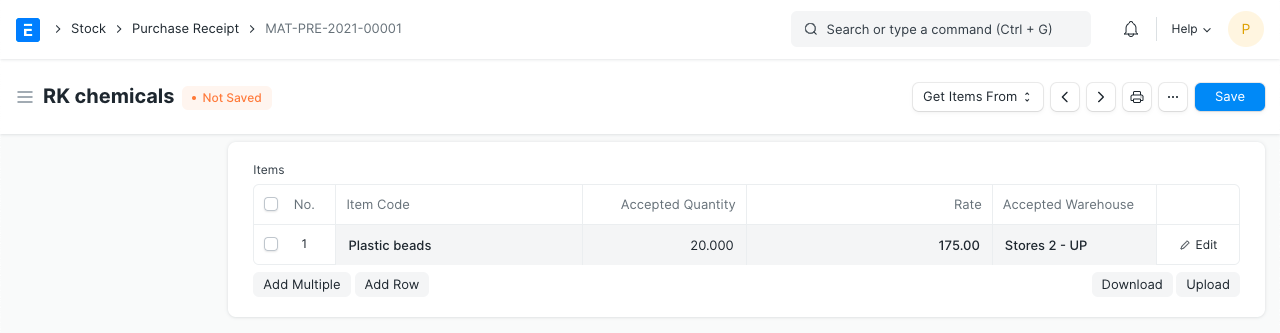

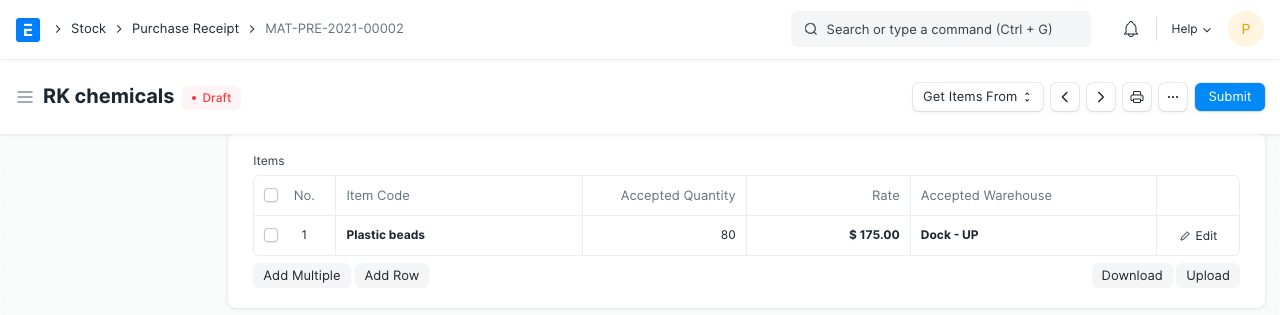

Let’s say, a company called ‘Unico Plastics Inc.’ ordered 50 drums of plastic beads. For the sake of simplicity, let’s say that they store such 1-ton drums in dedicated warehouse areas instead of racks and bins.

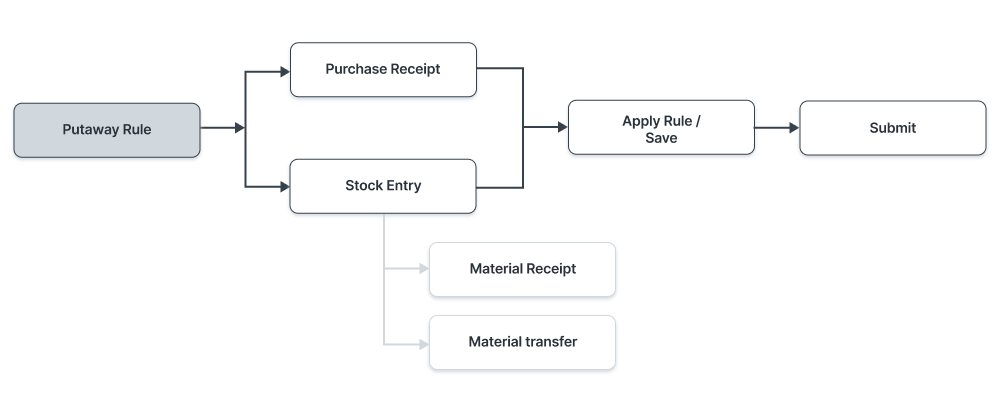

To get a fair idea, here’s a flowchart of the putaway flow in ERPNext:

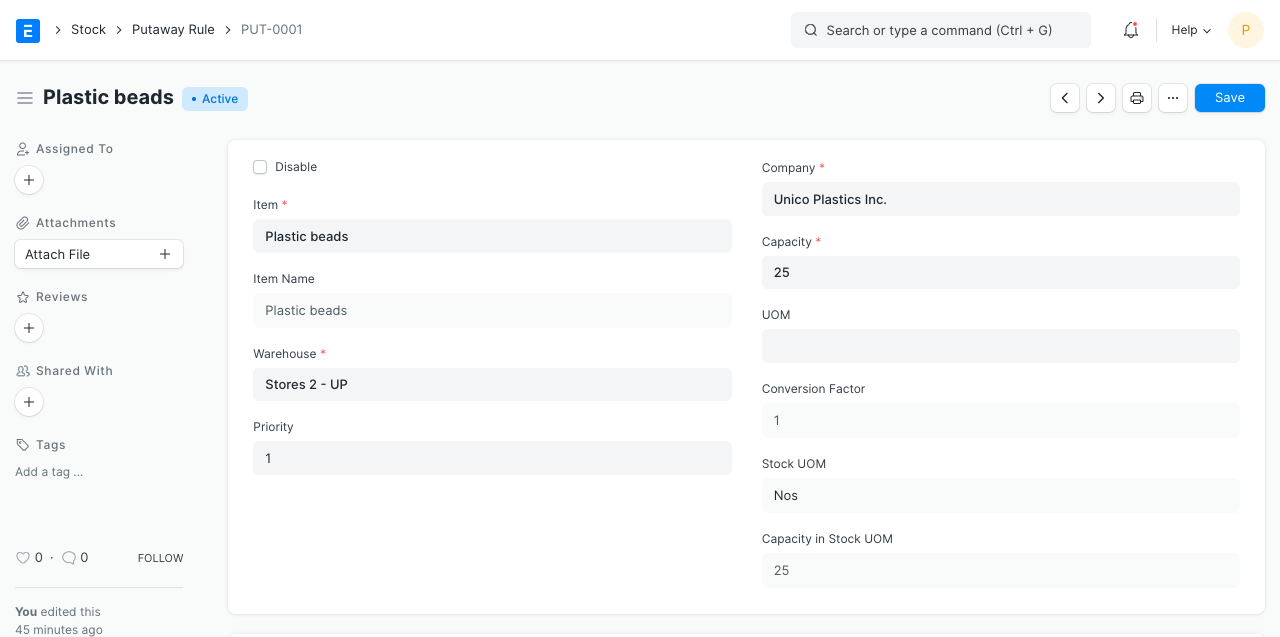

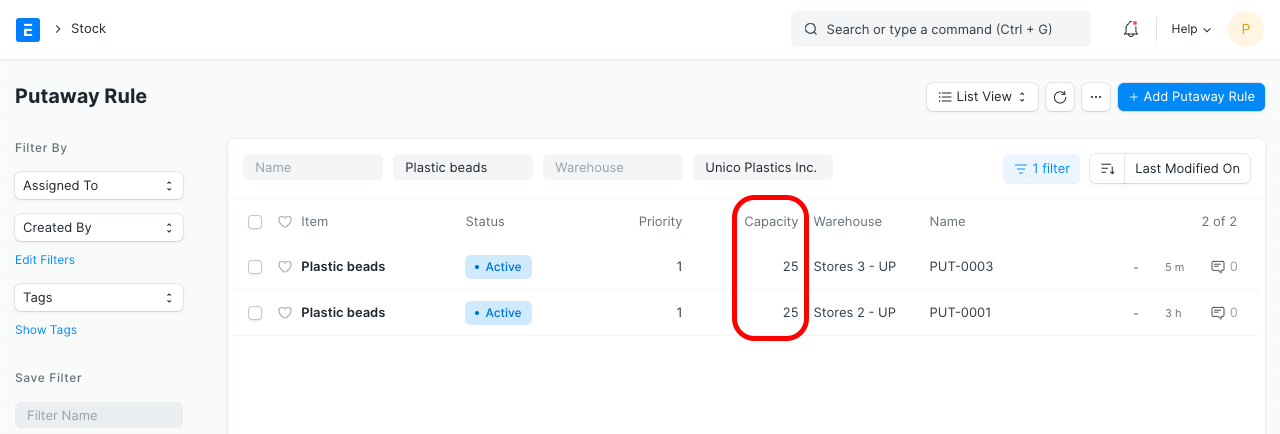

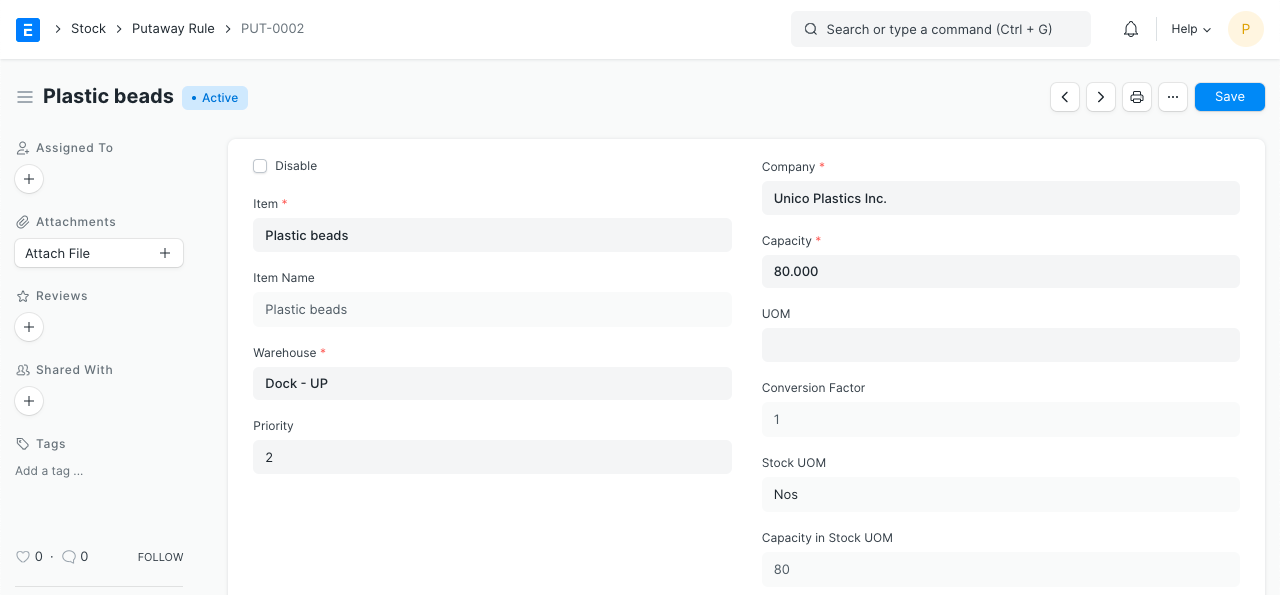

Now, a Putaway Rule for them would look like this:

As you can see, the capacity and warehouse is selected. You can also create sub-warehouses and name them as racks/bins/markings etc. The above Putaway Rule says that if 25 units of ‘Plastic beads’ come in, they need to be put away to warehouse called “Stores 2”.

The Putaway Rule kicks into action in Purchase Receipts and Stock Entries:

In the same example, if there are only 50 units of goods received, ERPNext would record the warehouse as half filled. So, if you try to receive a 100 unit putaway in the same warehouse next time, and the 50 units haven’t been used, you won’t be allowed to do that since there’s no storage space.

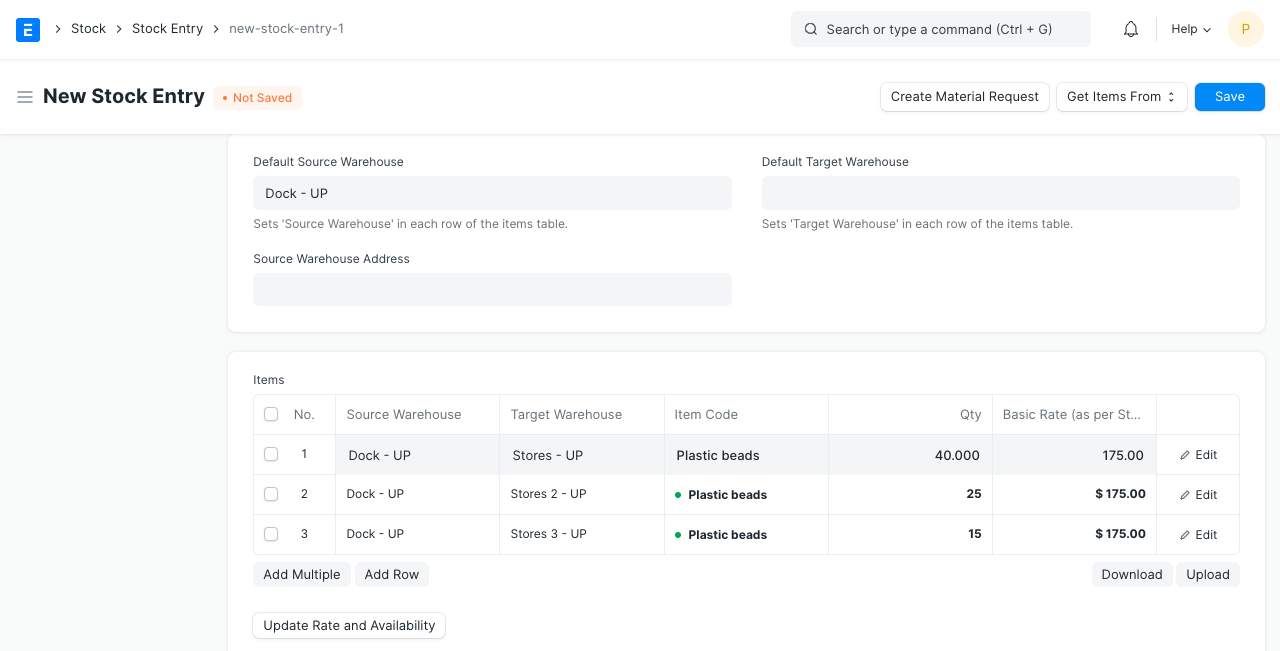

The way to solve this is by creating another Putaway Rule where the item would be the same but the warehouse would be different. So, when the quantity limit for a Putaway Rule overflows, ERPNext will automatically fetch the next warehouse for item putaway.

Here are two Putaway Rules for the item. There are two warehouses ‘Stores 2’ and ‘Stores 3’, each with a capacity of 25:

Here’s the Purchase Receipt with 40 incoming items, let’s see what happens:

As you see in the above GIF, before the Putaway Rule was applied, 40 units were to be accepted in ‘Stores’ i.e, the default storage warehouse. On clicking ‘Apply Putaway Rule’, the units were split and set to the warehouses recorded in the rules.

Direct putaway in ERPNext

Simply using a Purchase Receipt and applying a Putaway Rule achieves this in ERPNext. In this case, you’ll have all your Putaway Rules to target the end warehouse locations directly.

Indirect/combined putaway in ERPNext

For indirect putaway, first, receive the items using a Purchase Receipt into the temporary location. From here, do a Stock Entry to transfer the items from a temporary storage location to the final destination in the warehouse.

Here’s a Putaway Rule with a temporary location:

After this, you’ll receive items using a purchase receipt where the Accepted Warehouse will be something like ‘Dock’.

Now, here’s a Stock Entry to move the items from temporary to the final location:

Dynamic putaway in ERPNext

If you don’t assign a priority to your Putaway Rules for a certain item, it becomes a dynamic putaway in ERPNext. So, the most immediately available warehouses will be fetched.

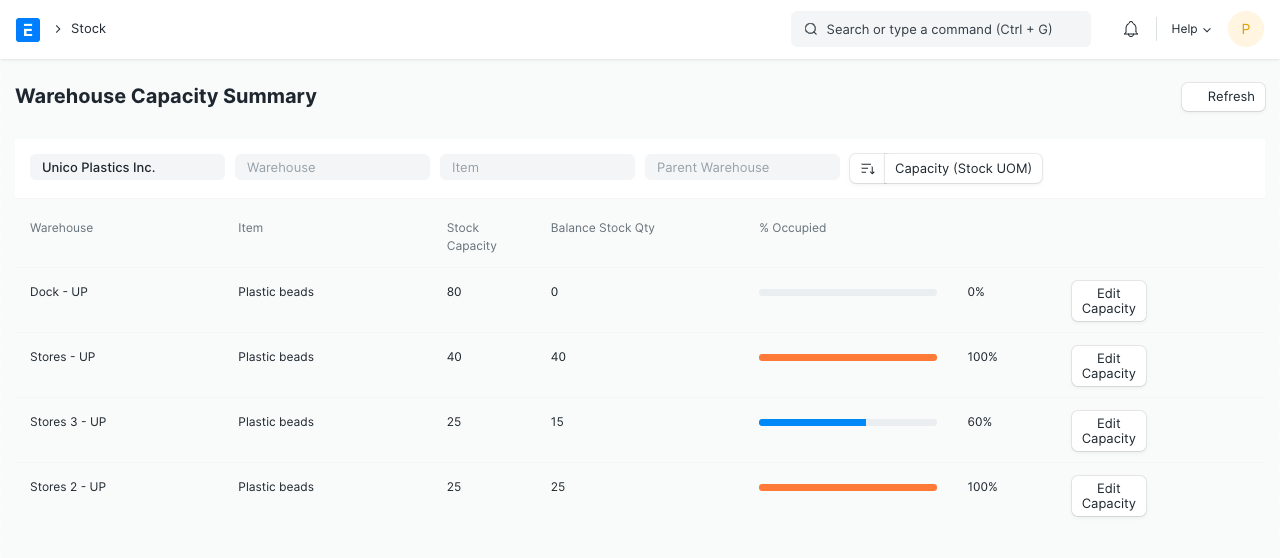

How to find which warehouses are available?

The ‘Warehouse capacity summary report’ report was introduced with the Putaway feature. It shows the capacity of your Warehouses. This is a quick way to check the availability of space among your warehouses.

3 putaway mistakes to avoid

Human error and not using software lead to mistakes when practicing putaway. Let’s see what they can be.

1. Items putaway at the wrong location

After new inventory lands near the warehouse, the items need to be stored at a proper final location. Needless to say, putting items in the wrong locations will cause problems when picking items for production or for fulfilling customer orders. Even worse, items that require specific storage conditions can be put in the wrong location and may perish.

There are two possible causes for this mistake. Both are avoidable. The first is human error. The second is the lack of proper software to show correct information on space availability and priority.

2. Inaccurate tracking and quantity

Relying on simple systems like spreadsheets or worker knowledge for information accuracy on warehouse inventory isn’t scalable. It works only for very small warehouses. Lack of good tracking also means that during putaway, certain warehouse locations may be overfilled with quantity while some may be totally empty. Or vice versa. And this may not be the ideal storage strategy you’d want to best operational efficiency.

3. Delays in putaway to location

This problem is posed in indirect putaway since items are first stored in a temporary area. It’s a problem if items are not putaway in schedules since in fast operations, the temporary storage space may get overloaded and this will put the warehouse in a tough spot if more items are incoming.

Conclusion

Once you’ve decided your warehouse needs putaway, the first step is to identify strategies to be used. Then, look for software to manage it. Implementing an efficient putaway flow ensures better inventory organization, easy access to items, and efficient use of space.

By listing down which strategies to use and software to go with it, Noah handles putaway in warehouses without a sweat.

Which putaway strategy are you going to use?

Prasad Ramesh

Marketing at Frappe.

Royal 4 Systems has a warehouse management system that can ensure that goods are stored at the right locations based on their storage condition.