Item Variants

Managing thousands of product permutations, such as screen size and RAM, is enormously complex. In ERPNext, the primary item is stored as an item template, and each of the variations is stored as an item variant.

Say goodbye to your legacy tools with a contemporary manufacturing ERP software that simplifies your computer manufacturing cycle and encourages innovation.

Trusted by Companies Worldwide

Computers have come a long way since their invention, but they still haven't ceased to inspire strategies for innovation. Disconnected legacy systems can result in inaccurate inventory forecasts, obsolete products on shelf, and bottlenecks in production. An innovative idea for a monitor is only the first part of the equation, but you need more than just that to run a successful manufacturing business.

Increase productivity, manage your supply chain smoothly, handle subcontractors, and exhibit MRP with a tool that provides not just production planning capabilities but an integrated inventory, document storage, supplier & customer management, on-the-fly customization and more! Don't leave money on the table — level up.

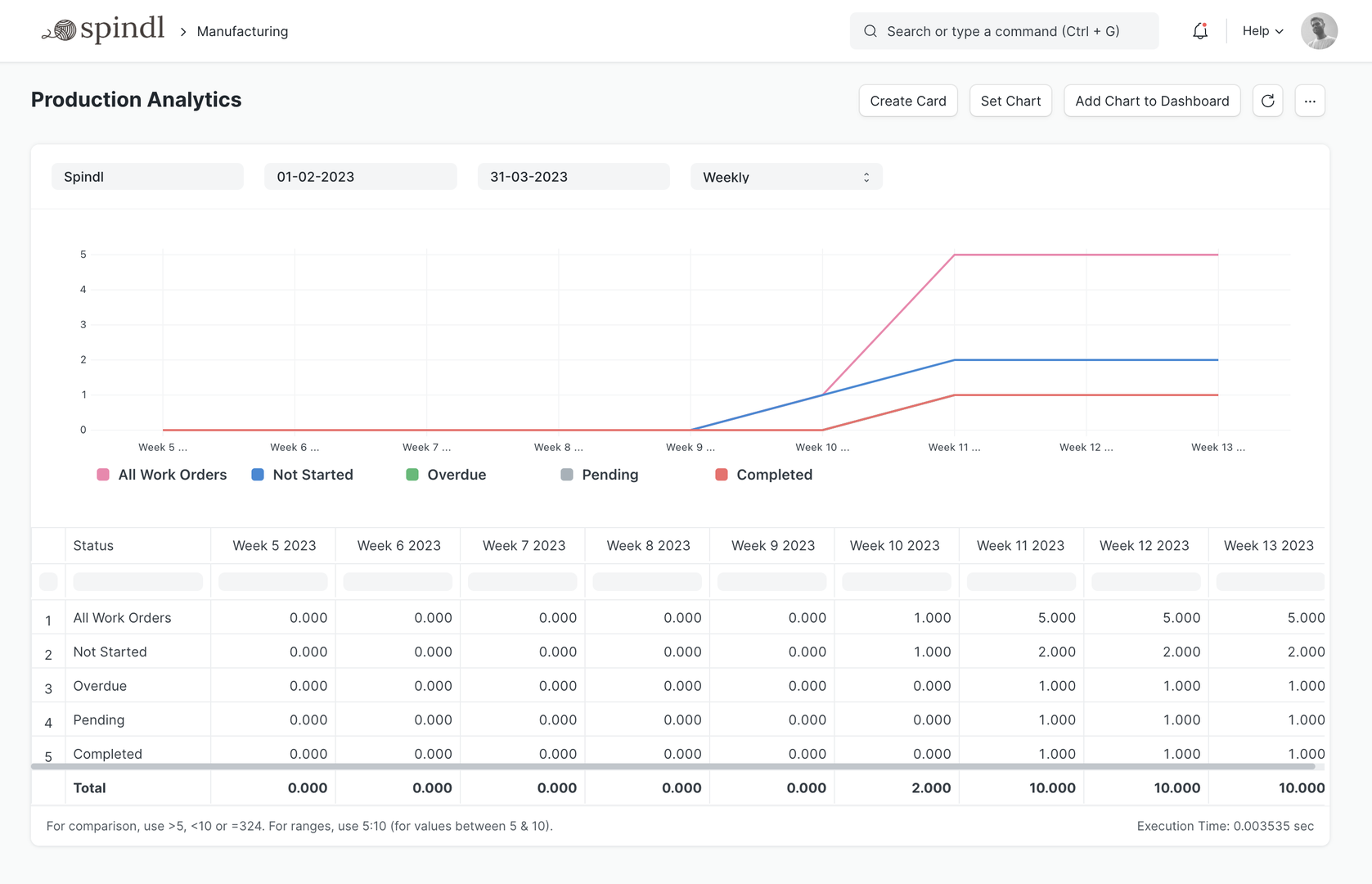

Keep an eye on your computer manufacturing business and ensure orders are fulfilled with our production analytics report — an aggregated view of production status.

Managing thousands of product permutations, such as screen size and RAM, is enormously complex. In ERPNext, the primary item is stored as an item template, and each of the variations is stored as an item variant.

A Bill of Material is at the heart of any manufacturing ERP software, and a well-defined BOM ensures robustness and accuracy. ERPNext's BOM is hierarchical, with the finished product at the top. It also includes item codes, raw materials, quantities, costs and additional specifications.

Navigate through the multiple levels of your BOMs and understand the foundation of your computer products. With the BOM browser, you can not only view the BOMs of sub-assemblies, but also update them in real time to maintain accurate costs based on stock value and ongoing procurements.

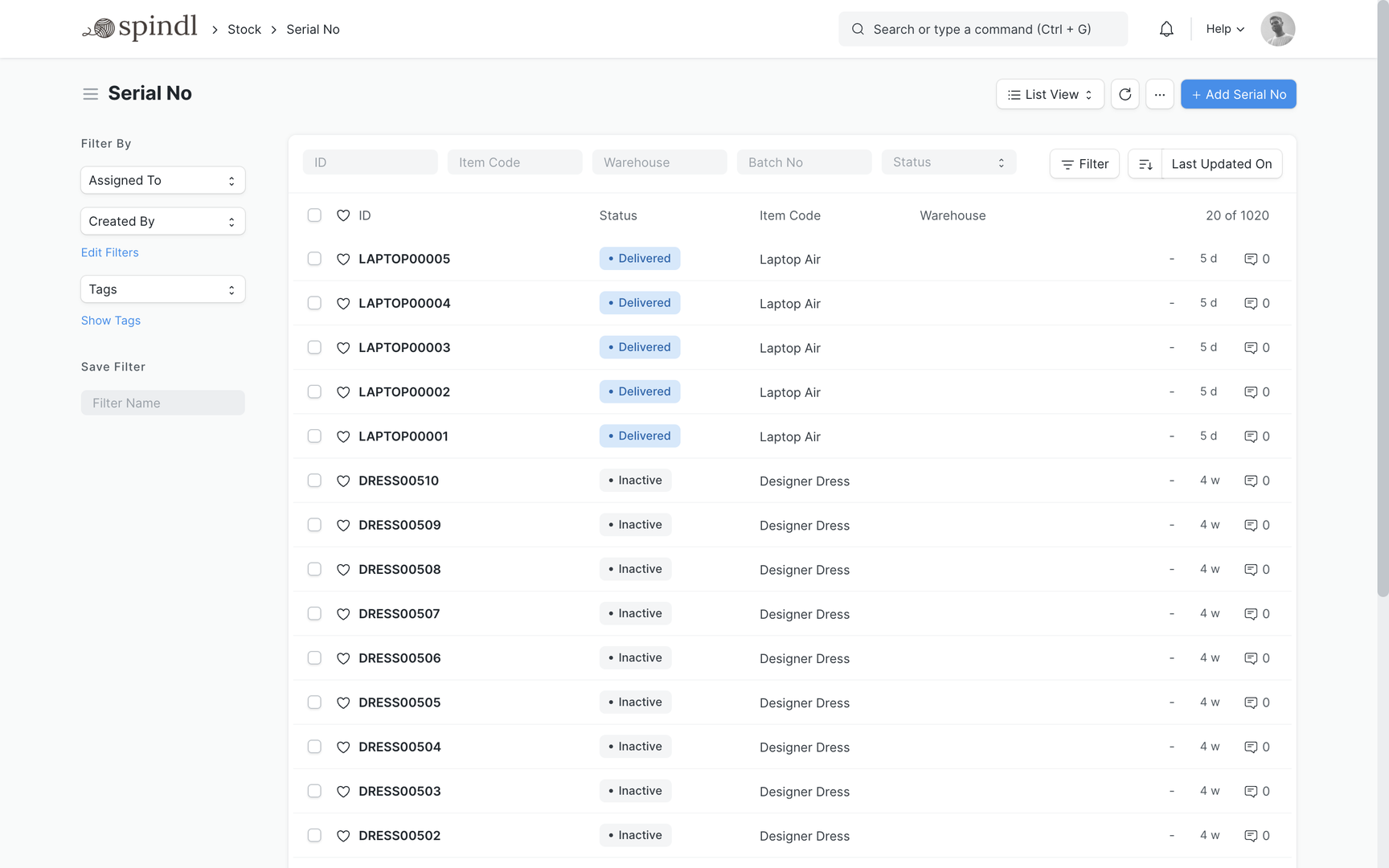

Without a serial number attached to it, a computer is incomplete. With ERPNext's integrated inventory, you can manage serial numbers, or even automate their creation based on your pre-defined series! You'll get a real-time view of the stock, ongoing transfers, pending receipts, and delivered products. Scan stock using either item barcode or serial number — no obligations.

Material procurement and production planning for computer manufacturing can become a nightmare. Be it a work order against sales or material requests, ERPNext will show every aspect of your MRP. Track material consumption of batched inventory to curb expenses and achieve zero wasted resources.

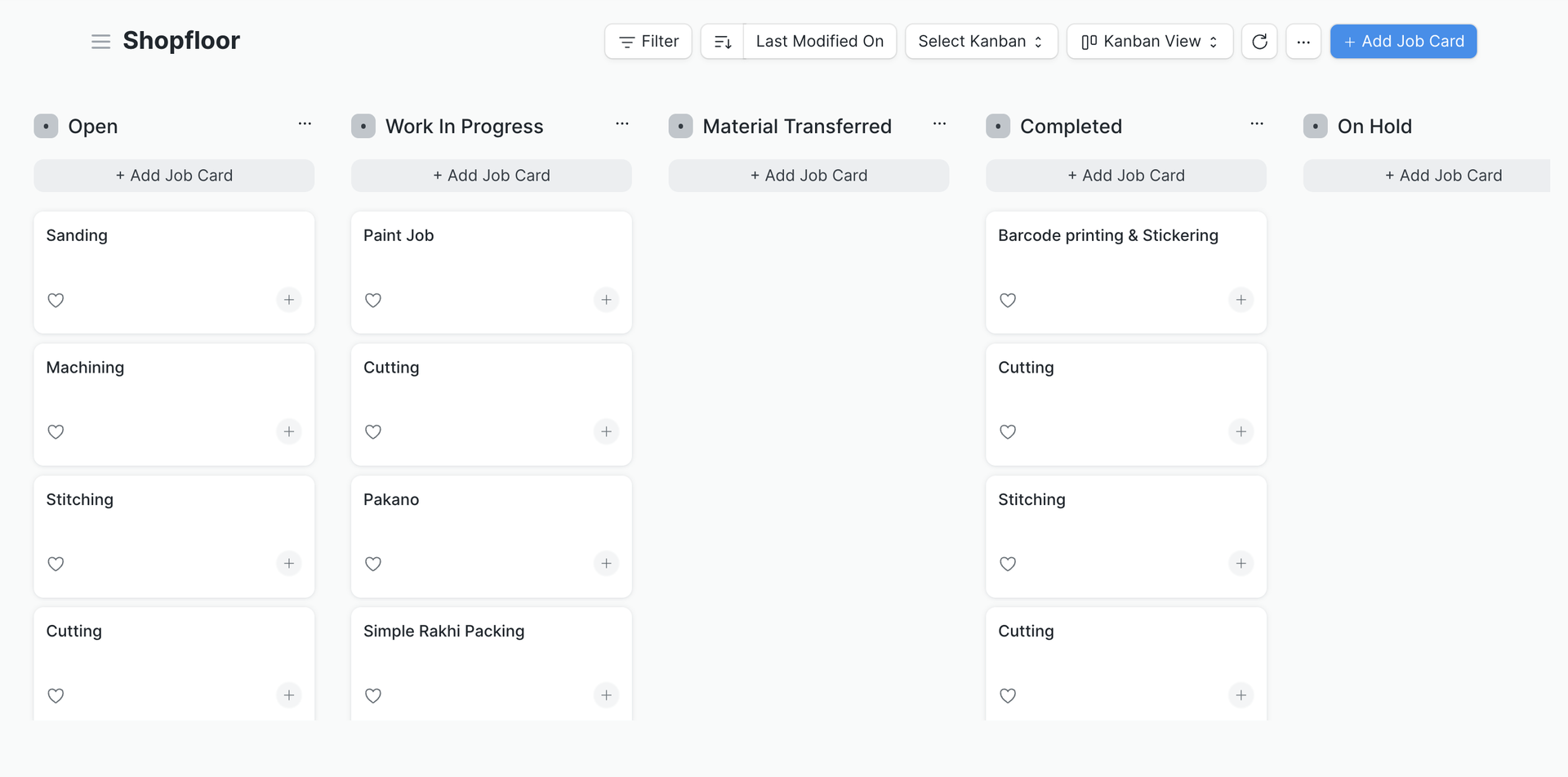

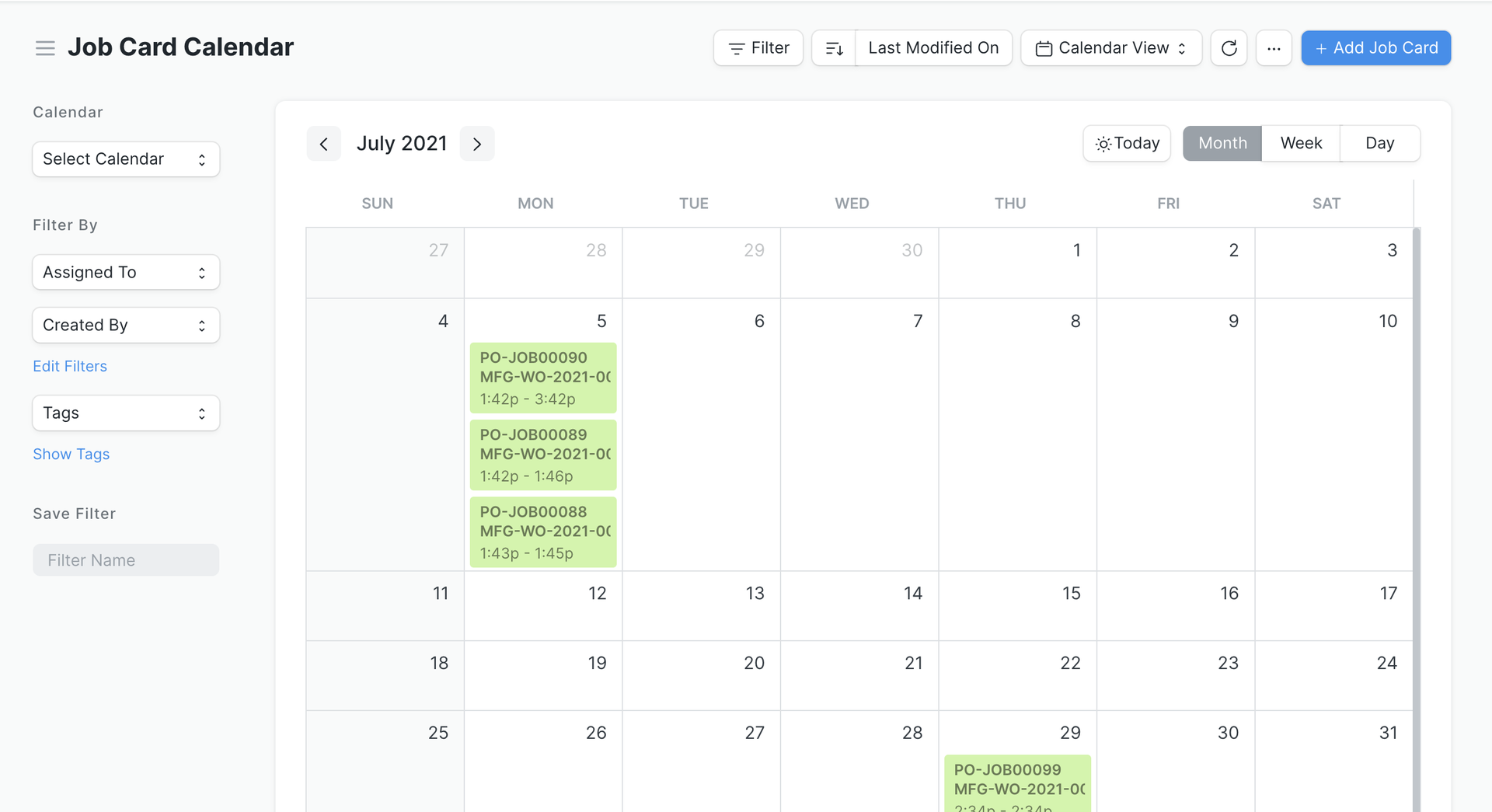

With the job cards, operations, and workstations features, you can automatically capture mundane activities on your shop floor. A single screen shows the real-time status of job work, the location of each workstation, employee assignments, and the status and next steps of each work order.

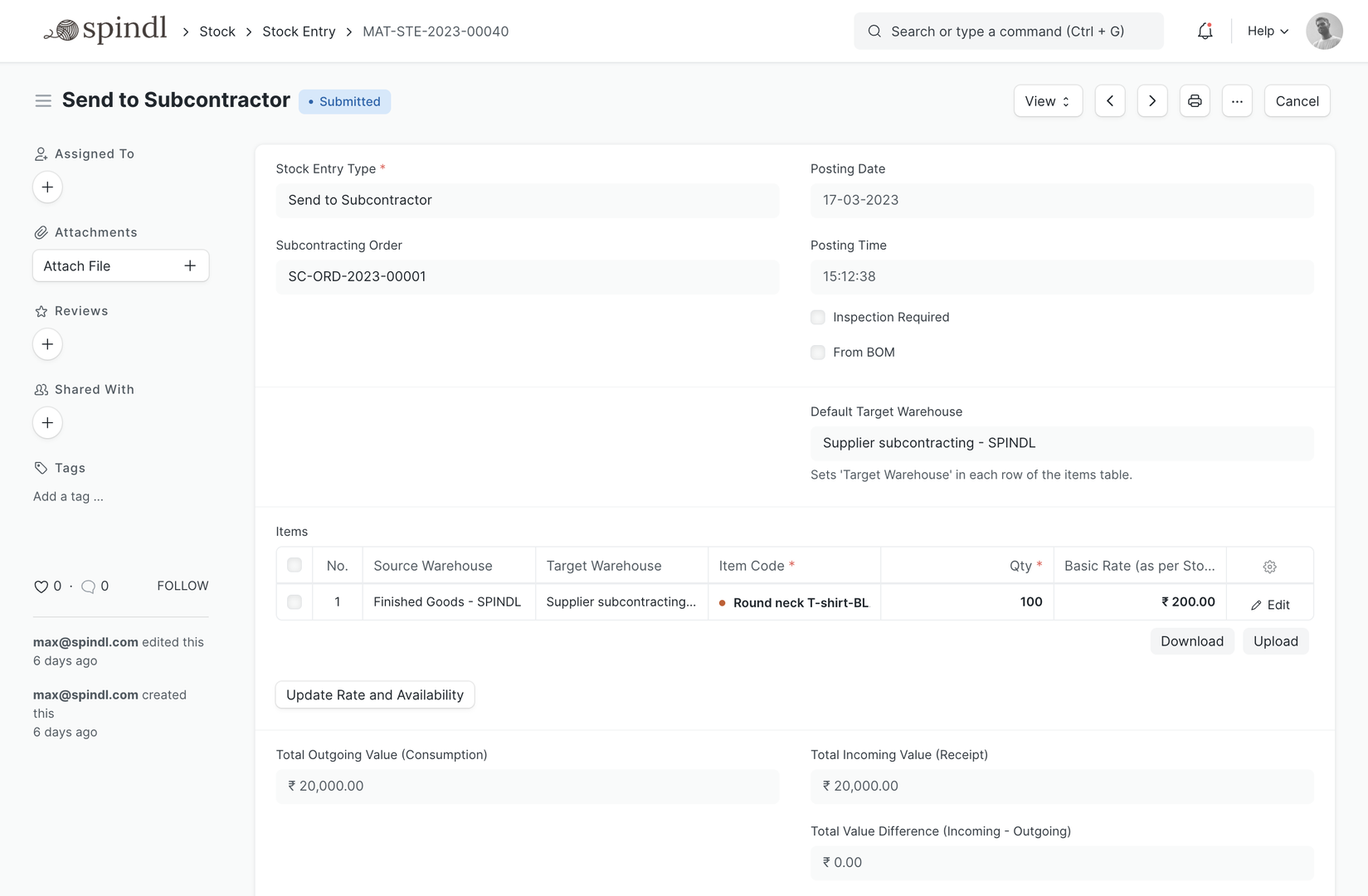

To maintain a smooth computer manufacturing line, you may need to subcontract work like eco-friendly packaging or CPU sub-assemblies. Use the Subcontracting feature to supply the raw materials to the third-party distributor or supplier and easily track all activities.

Optimize your workstations based on the resources available for open production orders. Identify and eliminate bottlenecks at the shop-floor level by creating a capacity plan. You can also maintain and manage planning schedules for a predefined period of time (30 days, 45 days, etc).

To prevent stockouts, track an item's reorder level. When the stock level goes below the reorder level, ERPNext will automatically create a material request. This helps you replenish inventory at exactly the right time and reduce chances of stock exhaustion.

Use the supplier portal to help suppliers manage themselves. The suppliers can submit requests for quotations and automatic supplier quotations, or access ongoing purchase orders and receipts. Suppliers can also raise purchase invoices for fulfilled orders. You can then verify these invoices for final approval.

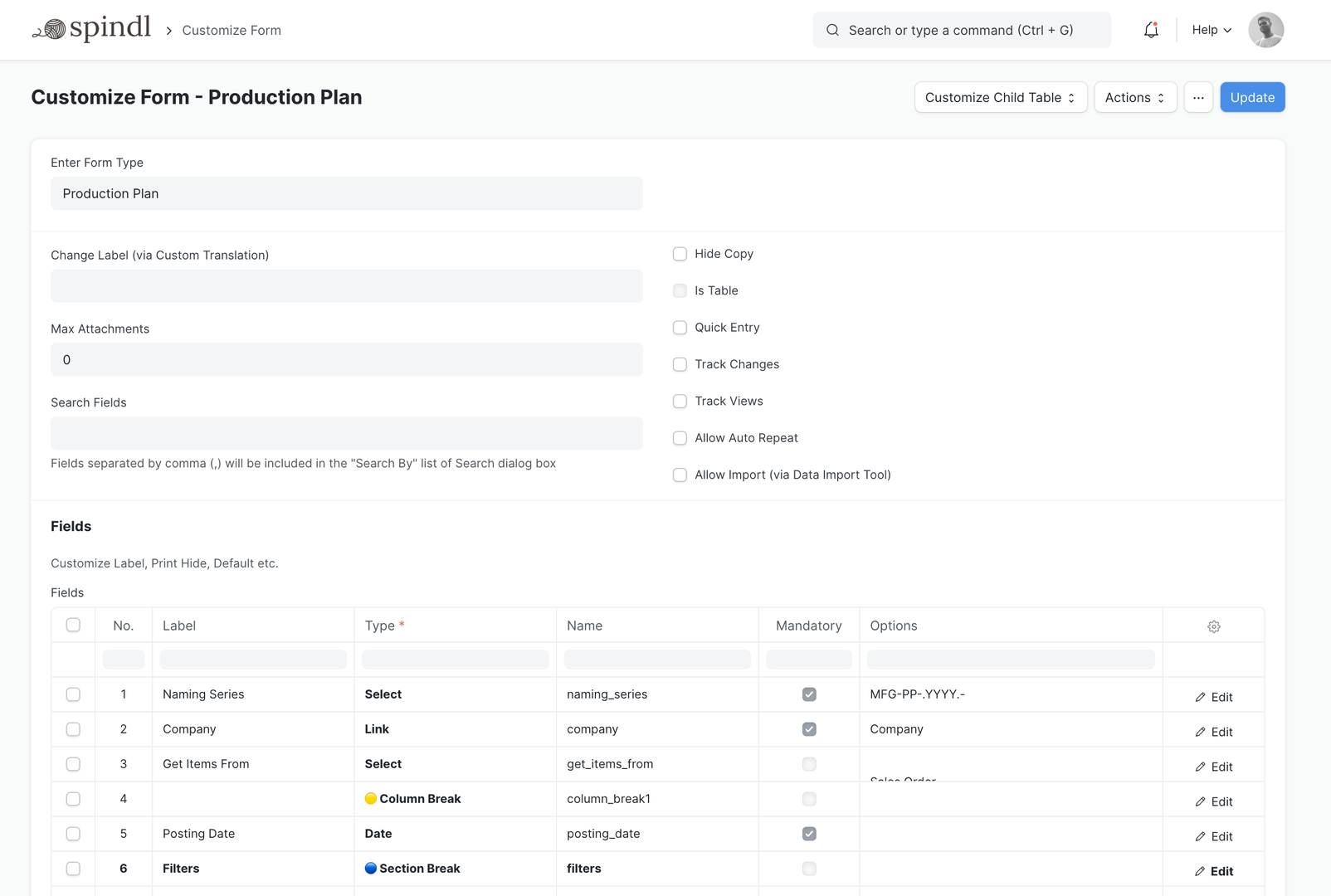

Create your own custom computer manufacturing ERP software. Map your most important data by adding custom fields in your forms. Customize form behavior by auto-fetching values, hide fields based on user roles, and create custom print formats — all without a single line of code.

ERPNext supports over 100 languages. Localizations build confidence while helping users feel welcome. Can't find your language? Help us translate: https://translate.erpnext.com

All the tools you need to achieve manufacturing excellence are part of the world’s first smart, DIY ERP. Transform your organization with excellent documentation and video tutorials that facilitate a zero-touch, super fast ERP implementation.

Open Source Software for Modern Businesses

Get a real time view of your cash flow. Full fledged accounting module covering every aspect of book keeping.

Manage full employee life cycle right from onboarding, payroll, attendance, expense claims, assets to separation.

Effectively maintain and manage multilevel bill of materials, production planning, job cards & inventory.

Increase productivity and lower costs by managing your sales and purchase cycles, from purchase to sales orders

Win and retain more customers by optimising sales process. Track leads, opportunities and send the quotes on the go.

Deliver both internal and external projects on time, budget and profitability. Track tasks, timesheets and issues by project.

Deliver a better service experience with an intuitive issue tracker and integrated knowledge base.

Maintain and Manage details of assets, their movement, value adjustment and depreciation.

ERPNext comes with a fully featured content management with blogs, web pages and forms.

ERPNext has a host of built-in integrations that help your business take-off faster

ERPNext has a host of built-in integrations that help your business take-off faster