What is MRP and do you need it?

A simple take on what is MRP and its benefits. Let's see if your business needs material requirements planning.

This is a more specialized concept particular to the manufacturing domain.

MRP simply means material requirements planning. Let’s try to understand this concept with a story first. Then we’ll dive into more details like the benefits of using an MRP system, the difference between MRP and ERP, explore alternative methods, and try to decide whether you need an MRP system.

Consider a company called Frappe Furniture. They’re new and have 12 customers. Every month they get an average of 25 orders. Each order requires the purchase of about 15 different types of raw material and consumables. The shop floor manager, Ron, records the orders and required materials in spreadsheets. Six months later, the company has become successful with 78 customers and an average of 277 orders. Recording orders and raw materials in spreadsheets had become difficult. But Ron had a bigger problem on his hands, planning the raw materials to prioritize the orders.

Say, if Ron had to manufacture 60 tables in 6 weeks. It takes a total of 4 weeks to manufacture the finished product. In this time, operations like cutting, assembling, painting and others are done. These are required to reach the final product. But Ron handles multiple orders due in close date ranges. Now questions arise like how to prioritize raw material procurement, consumption, and which stations to use for manufacturing. Understocking and overstocking both are inefficient ways to run a smooth manufacturing line.

Decisions like these and many other related ones need to be taken when performing material requirements planning.

So what is MRP?

In simple words, material requirements planning (MRP) involves planning your inventory and manufacturing processes to fulfill customer orders efficiently. From our example, if Ron were using an MRP software instead of spreadsheets, he would get answers to questions like “What raw materials to order?”, “When to order them?”, “What quantity?”. In fact, most software today already answers these questions and automatically creates material requests (requisitions)/procurement orders enabling manufacturing operations to run smoothly.

Say if we want to create a cupboard as a finished product, the racks, drawers, doors, etc will be “sub-assemblies”. By combining the sub-assemblies, we get the final product. The sub-assemblies themselves will require raw materials and processing. The list of items required to create a sub-assembly/product is known as a bill of materials (BOM). The BOM can contain individual raw materials and sub-assemblies. The ones with sub-assemblies are called multilevel BOMs.

Did you know? In the 1970s, MRP software was one of the bigger steps towards creating what we today know as ERPs.

What does MRP software contain?

Now that you have an idea about what an MRP is, let’s take a look at what it contains. The term ERP has clouded MRP in the 21st century. An MRP system is a large subset of an ERP system. From a manufacturing perspective, here are some common MRP software features:

- Production planning

- Bill of materials (BOM)

- Work orders

- Shop floor management (using work stations efficiently)

- Forecasts/reports

- Sales and purchase orders

- Accounting features to bill items

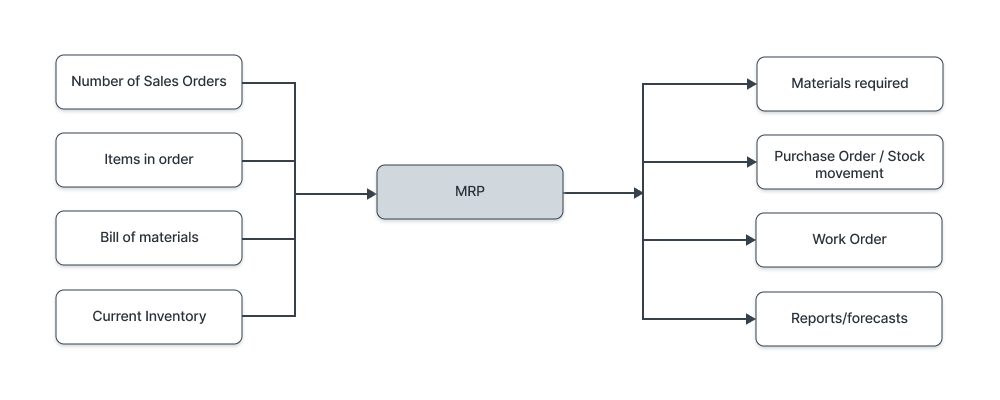

To give you a picture here’s a very basic idea of what an MRP system does:

It takes items on the left as input and gives items on the right as output.

Benefits of using an MRP system

1. Correct inventory levels

Having excess or shortage of inventory, both are harmful. Inventory shortage means delayed production times and excess means you’re holding on to inventory that’s not needed. Result? Your money is locked up in inventory. How the sales order demand rises or falls depends a lot on what you’re manufacturing. The demand for components of products will depend on the end products themselves while the demand for spare parts can vary. Hence, a smart digital system for managing MRP is crucial.

2. Production efficiency - minimize lead times

An important number to measure to check production efficiency is lead time. Lead time is the time between your customer placing an order and you delivering it. By having the correct inventory levels, the finished goods are also produced efficiently. When the raw materials and sub-assemblies are all stocked properly, there’s no delay from this aspect. All orders can be scheduled correctly to different resources resulting in efficient production cycles.

3. Prioritizing production of items

Consider you’re building a table and the wood for the tabletop cannot be made until 2 weeks but the order is due next week. It takes 6 days for the whole production process. Rather than building the other parts now and waiting for the tabletop, you can plan to manufacture other orders while manufacturing tabletops is possible again in one week. This way, half-finished products will not be idling in your inventory. MRP systems assist managers in making such smart decisions.

4. Calculate material requirements

When you receive the next order, you don’t have to worry about the raw material requirements. Enter info in the MRP system and it’ll show the raw materials required. By calculating the required raw materials for all orders, MRP software saves a lot of time for manufacturing businesses. This is especially true where large quantities are involved.

MRP vs ERP

When first introduced, MRP systems had features specific to manufacturing. As technology progressed, more tools were joined together. In 1990, Gartner coined the term ERP (enterprise resource planning) software. Today, MRP systems are a subset of ERP systems with most major providers bundling all MRP features under the ERP umbrella package.

Drawing a detailed comparison here would be moot. In a nutshell, MRP systems are manufacturing specific while ERP systems have features for all domains like CRM, HRMS, asset management, and others.

Alternatives to MRP?

In lean manufacturing, only a fixed number of items are manufactured. This eliminates wastes in exchange for doing less business. To consider lean manufacturing for your business, an important area to look at is the opportunity cost.

For example, Ron decides to manufacture only 100 pieces this year. Later in the year Ron may or may not get orders to produce 20 more pieces. This means he’ll say no to the extra 20 pieces. The question Ron has to answer is “What is the opportunity cost?” or “When will I lose more?”:

- By saying no to the probable 20 pieces

- Risk idling inventory for 20 pieces if no order was secured

Lean manufacturing minimizes variance. If Ron knows that Frappe only needs to manufacture 100 pieces of furniture this year and it’s okay to say no to 20 pieces that may or may not be ordered, then lean is good for Frappe. Multiple factors like cash flow, warehouse space, time to manufacture, variance in raw materials, variance in produced items both in numbers and types, etc., should be factored into making this decision.

Lean works well in areas where the same type of items are manufactured in regular quantities. In such cases, the variance is low and predictability is high, hence it’s easier to stick to a fixed plan.

Should you use an MRP?

Answer to this question depends on a couple of factors, let’s consider them.

- What is the variance? (how many different types of items / variable volume)

- High variance (more types of produced items) = low predictability

- The type of manufacturing business your company does:

- Complete product manufacturing and assembly (like cars)

- Part manufacturing (for equipment parts)

- Assembly business (assembling parts)

- If there are a lot of items stocked in inventory constantly with delays in order fulfillment, it means there are inefficiencies in your manufacturing line and planning. Using MRP software properly can help eliminate these inefficiencies.

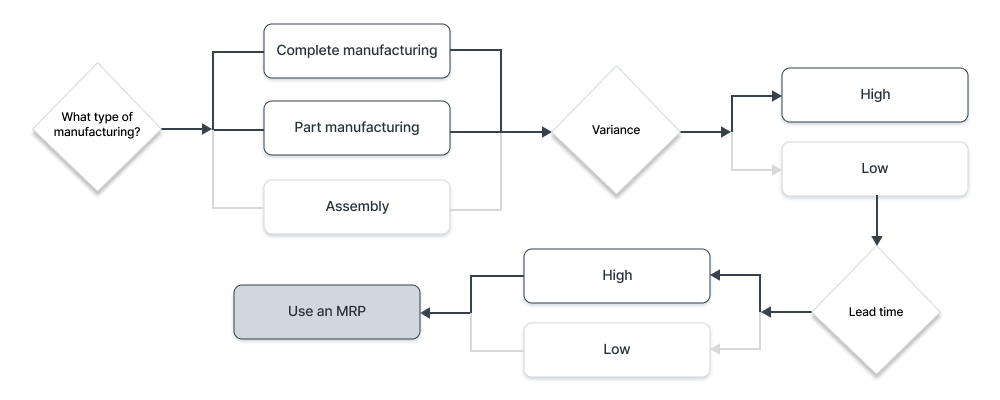

To help you decide whether you need an MRP software, here are some points to keep in mind when deciding:

In the above diagram, the paths and boxes with dark lines emphasize higher importance of using an MRP. The light lines mean that you probably manage without an MRP.

Conclusion

If your business involves full cycles of manufacturing, i.e. raw materials to operations to sub-assemblies to finished products, you constantly need to know your current inventory levels and how much orders you can complete with it. In such cases, you will greatly benefit from MRP software. Lean manufacturing is an alternative if your item type variance is low and order number predictability is high.

When MRPs were first introduced, options for other activities like CRM and HRMS were sparse and different software. Today, we have everything combined under one roof—ERPs.

Thankfully, modern ERPs have simple interfaces and responsive designs. ERPNext has features to manage manufacturing, inventory, and much more. Start a free trial.

Prasad Ramesh

Marketing at Frappe.

Yes, MRP is wonderful ;-) but it would be really helpful for us readers if there was a tutorial we could follow with a specific example, e.g. screenshots, workflow steps, links to video's (if a good tutorial already exists), etc. I've been trying to learn the process, but have still to successfully complete a representative production example.

@Deepak Nagar, from the little I know about "Demand Driven", Demand Driven MRP could be an effective option but I fear any progress will require first a champion who writes code (i.e. same as with Odoo).

It would be great if ERPNext upgrades to Demand Driven MRP.

More details at

www dot demanddriveninstitute dot com.

MRP as described has 50 year old logic suitable for conditions that prevailed then. The conditions are drastically different and hence the logic has to be upgraded.