What is inventory control? Its objectives, methods, and how to do it.

Inventory control or stock control determines your order fulfillment, profits, and dead stock. Let’s see how.

So you’re running a distribution center or a manufacturing line. You’ve figured out your suppliers and customers. But have you thought about everything in between? Yes, I’m talking about inventory control, something that can drastically affect your profits and customer retention if left unchecked.

Inventory control starts from the moment stock enters your warehouse till it leaves for shipments. It has to do with all the operational activities done to manage stock in the warehouses and different tactics employed to achieve continuous physical availability of inventory.

With the wide range of available software, inventory control also means quality control, tracking locations and bins, tracking items with barcodes, SKUs, and so on. By implementing an efficient inventory control system, you can optimize your stock to cut on what doesn’t sell and procure more of what sells fast.

In this blog, let’s understand everything from what is inventory control, its objectives to how to do it.

What is inventory control?

Inventory control refers to the use of techniques to control inventory in warehouses to minimize stock in hand while fulfilling customer orders on time. Various techniques like two bin method, quality control, barcode scanning, forecasting, etc., are used for controlling inventory.

What does inventory control depend on?

Let’s see the parameters that affect inventory control.

- Item lead time

- Shelf life of perishable items

- Seasonal inventory items

- Customer demand

- Available storage space

Inventory control objectives

We’ll talk about inventory control in more detail soon but before that, let’s see what are the objectives of inventory control.

Ensure stock availability

Having the right inventory levels is only a part of the problem to ensure smooth flow of goods in warehouses. For a manufacturing company, there are bottlenecks caused by disorganized warehouse structures or related items being placed too far away. Inventory control’s objective here is to ensure a steady supply of raw materials and subassemblies (manufactured or outsourced) from the warehouses without interruptions for fulfilling manufacturing orders on time. This also applies to distribution businesses where inventory has to be picked and packed for shipping orders.

Prevent wastage

Inventory waste happens in two cases—either the stock is defective or the stock has expired. It also happens when stock is idle and there’s no market demand. Here, inventory control aims to prevent defective stock from entering your warehouses with quality control, and to prevent dead stock or accumulation of expired items.

Maximize profitability

Poor inventory control impacts profits negatively. This is not surprising once you realize that one of the other objectives is avoiding stock wastage. Not only that, but poor inventory control also means difficulty in picking items from warehouses where required, be it manufacturing orders or distribution activities. If the orders are not fulfilled on time, customers won’t be happy. Hence, good inventory control positively impacts revenue in two ways—by avoiding money lost in expired stock and eliminating any inefficiencies during stock movements between storage areas.

Save storage space

Stocking inventory requires physical space. Actively managing your inventory, warehouse layouts, locations, saves on warehouse space and hence rent costs. It also involves doing away with excess stock, dead stock, and expired stock. If your storage areas are planned well and aren't occupied by dead stock, you’ll be saving on storage space for the products that sell better.

6 Inventory control methods

Let’s talk about inventory control methods, techniques, and formulas. As we already discussed, today, inventory control is a lot more than simply counting stock.

1. Two bin method

To avoid inventory shortage, the items are stored in two bins. When the first bin becomes empty, stock from the second bin starts getting used and at the same time, replenishment is done in the second bin.

2. Barcoding

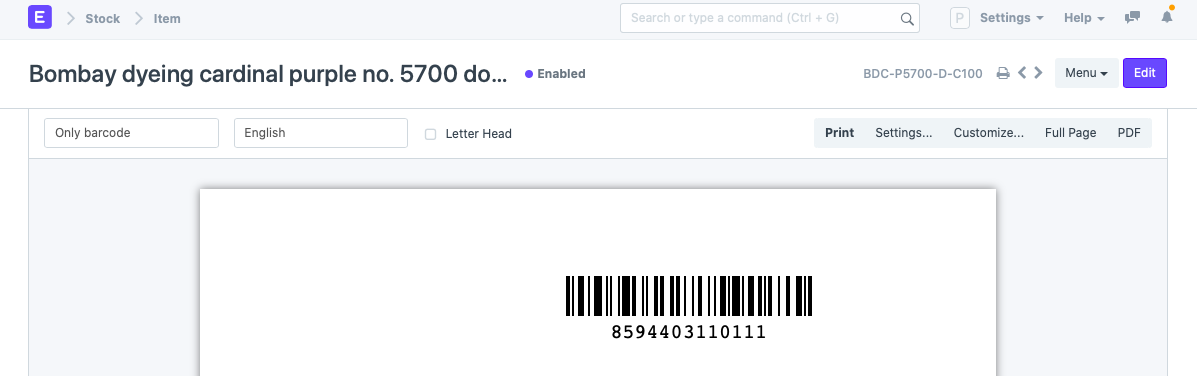

UPC/EAN barcodes are black lined symbols with 12 or 13 digit numbers under the lines. In ERP/inventory software the printed barcodes can be scanned to update quantities in transactions. It’s similar to what you see at the cashier in a store but industries may use wearable barcode devices for better efficiency.

3. Labelling

Labeling refers to identifying different inventory items with specific labels. Barcodes are used universally to identify units but in warehouses, companies use SKUs to track different types of items. Labeling via easy to read SKUs helps to find and pick stock for shipments.

4. FIFO and LIFO

Using inventory is done in two ways FIFO and LIFO. Both have their advantages and industries where it makes more sense to use them.

- First in first out: The oldest units are chosen for orders. It’s common when companies deal with perishable items. Batch numbers are associated with expiration dates and simply the older batches are selected for order fulfillment.

- Last in first out: The newest units are sold first. Although uncommon and even impractical for perishable items, LIFO is done in industries where the cost of acquiring new goods is ever increasing. It benefits revenue booking and reduces tax liability.

5. Stock bundling

Bundling different items together to create product bundles is a common operation that helps companies introduce new products or sell older ones that are sitting idle. Simply creating bundles with new/old items with popular products increases sales, you can also offer discounts on bundles to make attractive deals and speed up sales.

6. Quality inspection

The operations of controlling the quantity of stock items falls under inventory control. However, the act of setting and defining the quality standards is a part of inventory management. From a control perspective, regular quality inspections when the stock enters and exits warehouses should be mandated. Over time you’ll find suppliers that consistently send quality materials. In case of a manufacturing business, you should consider incorporating concepts like lean and six sigma to increase quality and reduce defects.

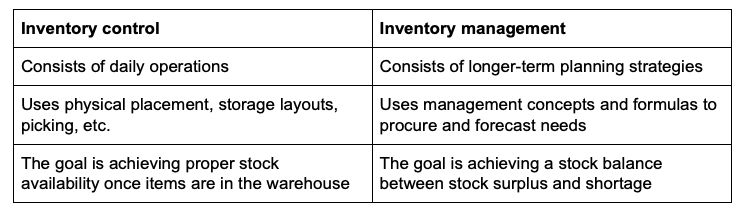

Inventory control vs inventory management

Although they sound similar, inventory management is a broader concept that encompasses everything from stock procurement to selling it to the customer. Inventory control is more about daily operations that take place in warehouses to prevent inefficient movement, inventory expiration, wastage due to bad quality, etc. Here’s a table to explain the differences:

Inventory control system (ERPNext)

Let’s see the different inventory control parameters and techniques in action with software. Consider this an example of inventory control driven by ERPNext.

Before getting into inventory control, you’ll choose the best suppliers and procure the required items in the early days of your business. A few weeks in is where you’ll have to think about inventory control problems like automating stock counting in transactions, shelf life, quality, wastage, bin placements, stock grouping, etc.

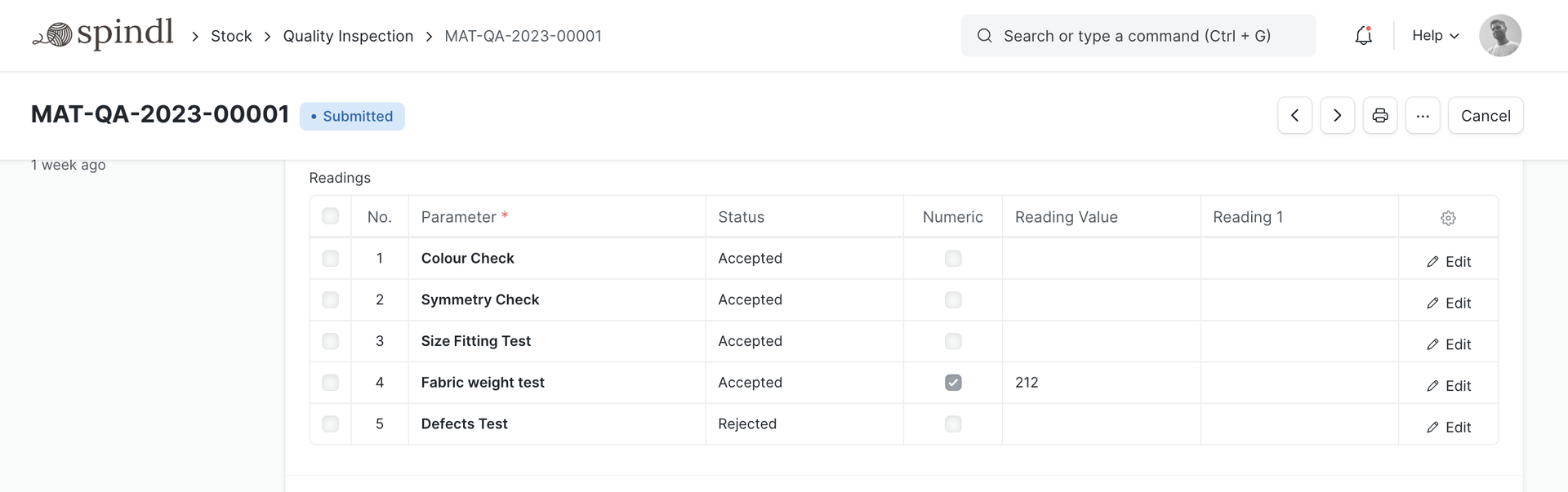

1. Quality control and inspection

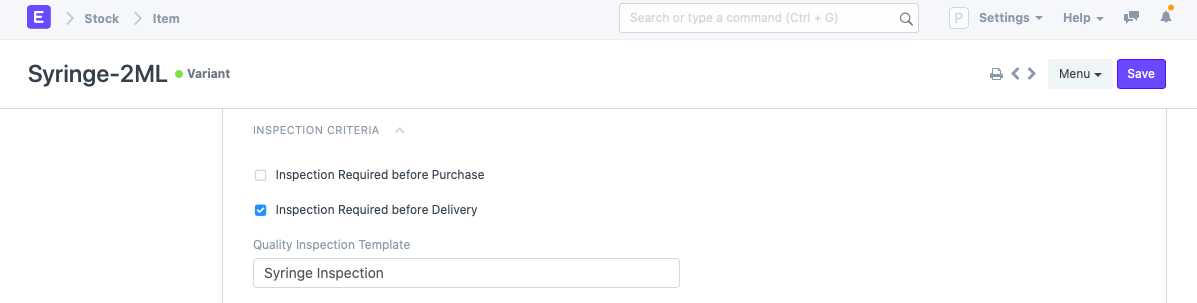

Every item or batch that enters your warehouse should be inspected before being accepted. You can set the parameters for different items based on what qualifies good vs defective units. In the below example, for a medical syringe, we’ve demonstrated parameters like needle sharpness, damages to body, etc.

To enable this in ERPNext, go to the item form and enable the inspection required options. Quality inspections can happen when receiving items to your warehouses and also when it leaves your warehouses for delivery.

2. Scanning barcodes for auto update

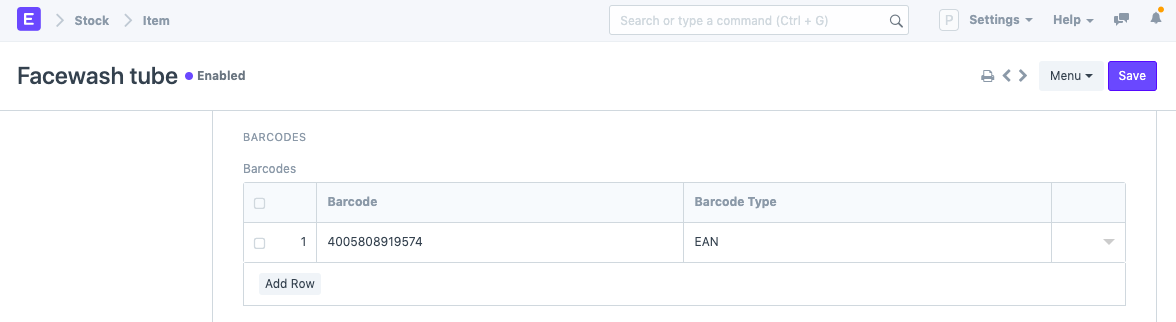

Manually counting inventory is boring not to mention takes a lot of time. By printing and sticking UPC/EAN codes to items and running a barcode scanner, you can automatically update the quantities in your stock transactions. Simply having the familiar UPC/EAN barcode stuck to items and scanning them quickly to auto update information in your software system saves a few seconds on each item. But hours and even days when doing large quantities.

After a point, using barcode scanners is easier than manually entering stocks. In stock entries and purchase/sales transactions simply scanning the stored barcodes will automatically update the quantity in your transaction.

First, you need a compatible barcode scanner connected to the computer/laptop. Then, you need to ensure that the UPC/EAN code is stored in the Item master. Scanning will not work if the code is not stored. But don’t worry, you only need to store this once for each item.

Now, simply use the barcode scanner and the item count will be updated in transactions. The barcodes can be generated and printed from here:

This also works with smartphones where you can use your smartphone’s camera to scan the barcodes. Note that this can be slightly slower depending on the phone you use.

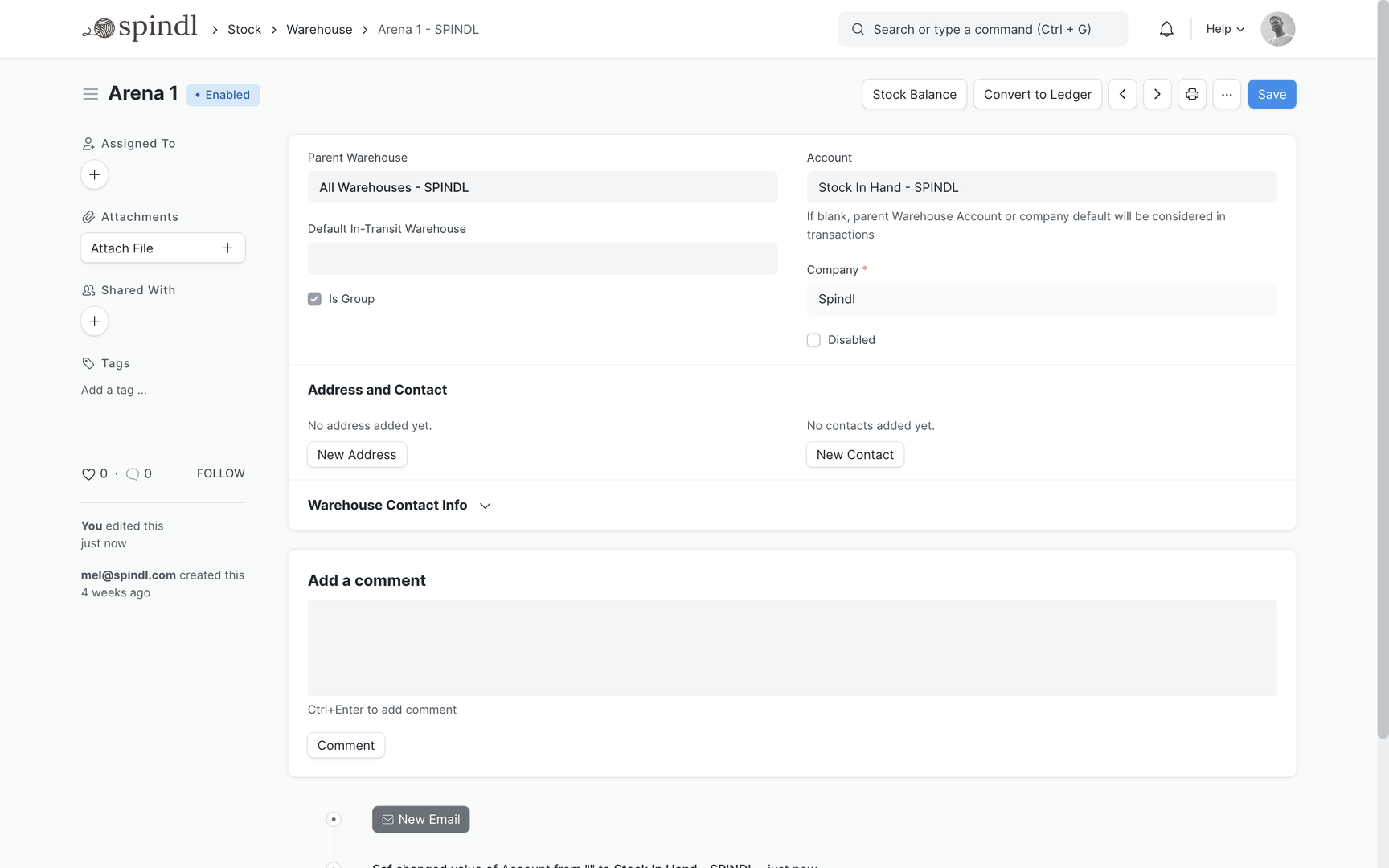

3. Warehouse account to know profits

To maintain company-wise stock balances, every warehouse must belong to a company. To enable this, every warehouse should be linked to a general ledger account.

By creating a ledger account with the same name as a warehouse, you can directly track all profits and losses tied with that warehouse. This will help you determine which warehouses are the most profitable by comparing it with the rents you pay or the efficiency of storage space being used.

To do this, create a GL account under the appropriate group account. Then, link the newly created warehouse to the warehouse of the same name. In the following example, the warehouse name is “Chawla Traders” which is linked to the account “Chawla Traders”.

After linking, the warehouse account will show up in the chart of accounts from where you can view the financials.

4. Ensuring correct stock availability

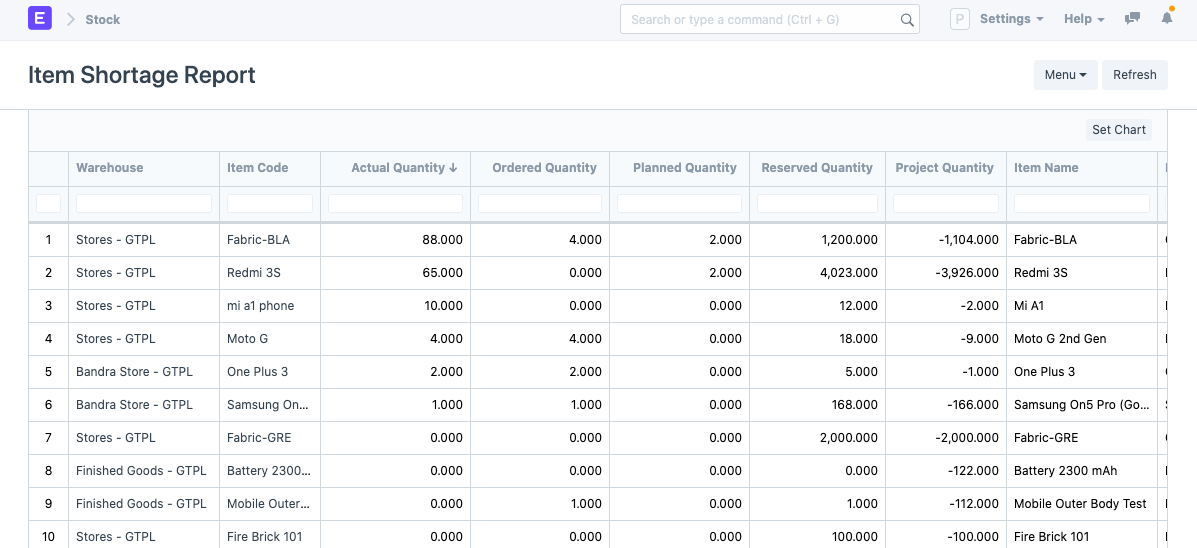

By using different stock reports in ERPNext, you can understand various aspects of your stored inventory. In the context of inventory control, let’s see a few of them.

The item shortage report gives details on actual quantity, ordered quantity, reserved quantity, and projected quantity.

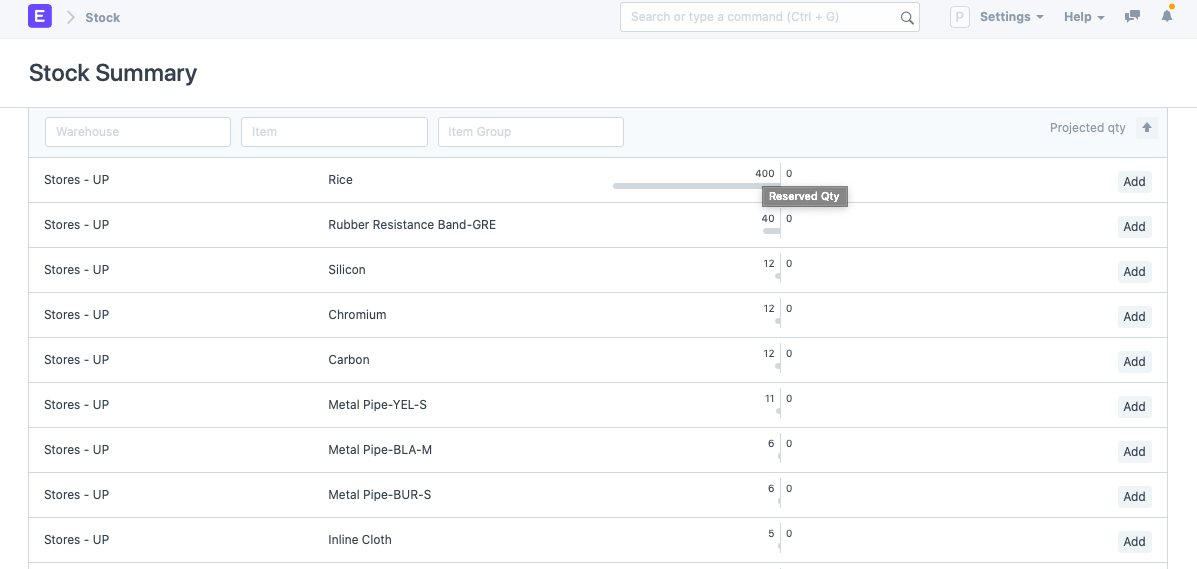

For a quicker view, the stock summary shows the reserved quantity and actual quantity of different items.

5. Stock shelf life

Another important aspect of inventory control is shelf life. If you store items that have an expiry date associated with them, this should also be factored into the decisions you make.

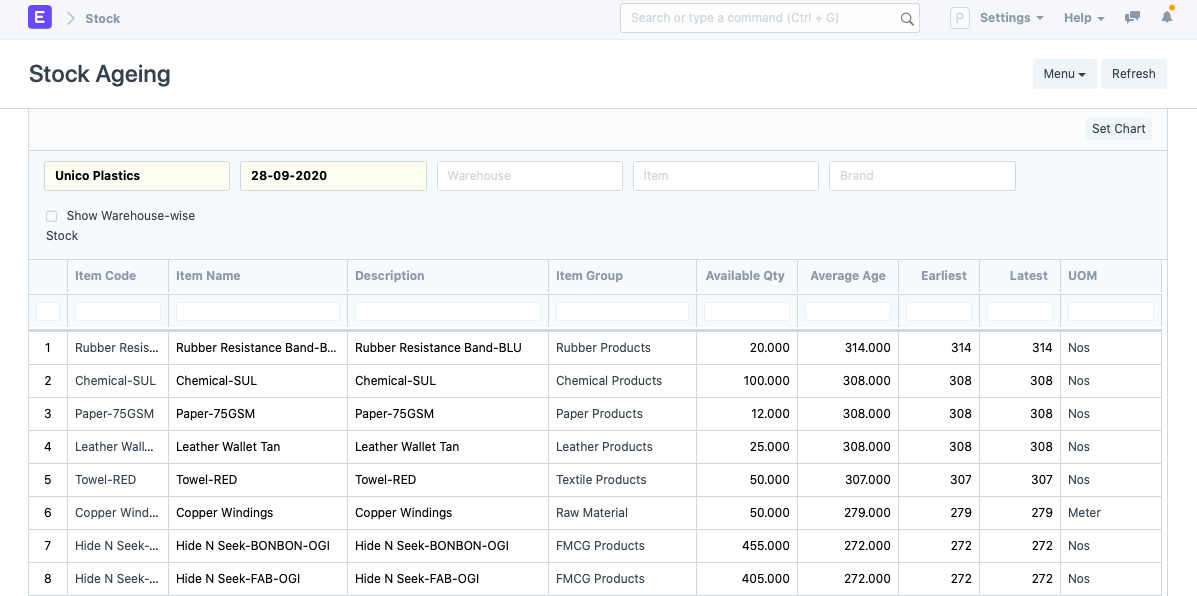

In ERPNext, see the stock ageing report to understand which items are close to expiry.

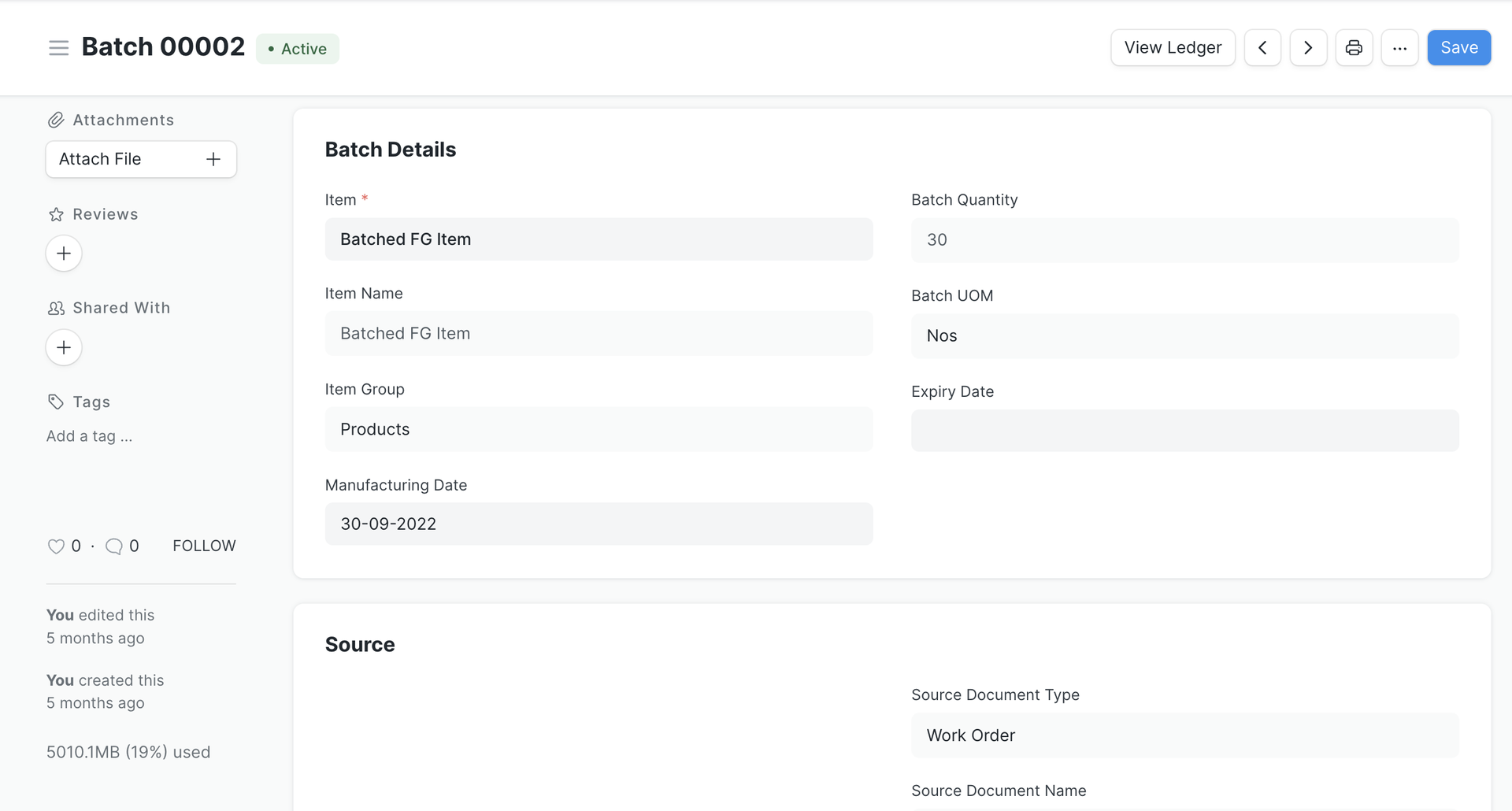

6. Batching inventory

You can also group items in batches which have their expiry dates. Batching enables you to identify the materials closer to their expiry date and avoid wastage. This is extremely important in case of pharmaceuticals and food items.

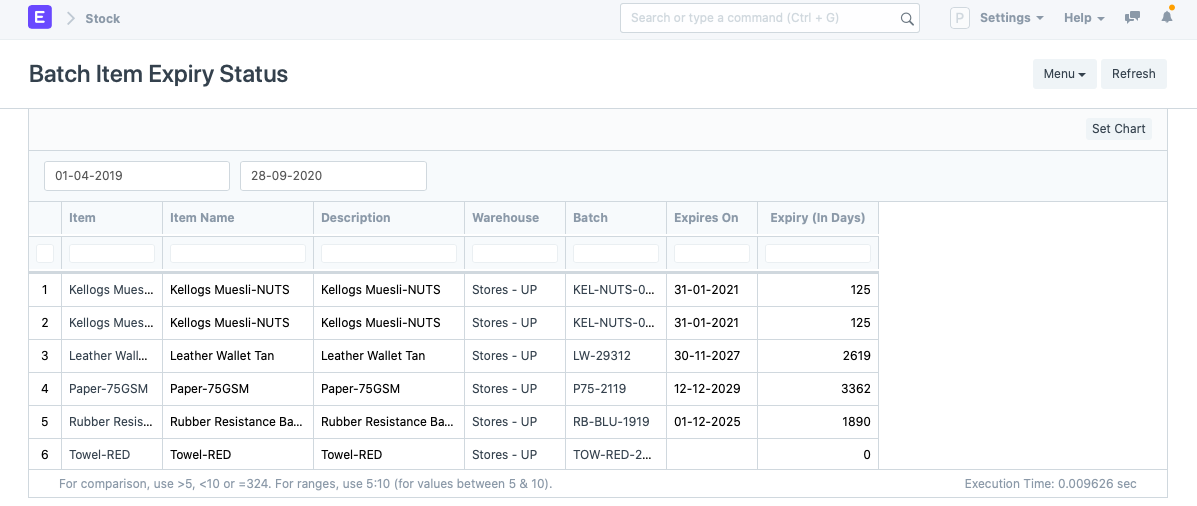

The Batch Item Expiry Status report shows the expiry date of items with batches.

7. Stock picking

Speaking of batches, when fulfilling customer orders, you’d want to manually choose batches whose expiry date is close. By using older stock first, you ensure that they don’t sit idle in your warehouse and end up being dead stock leading to losses.

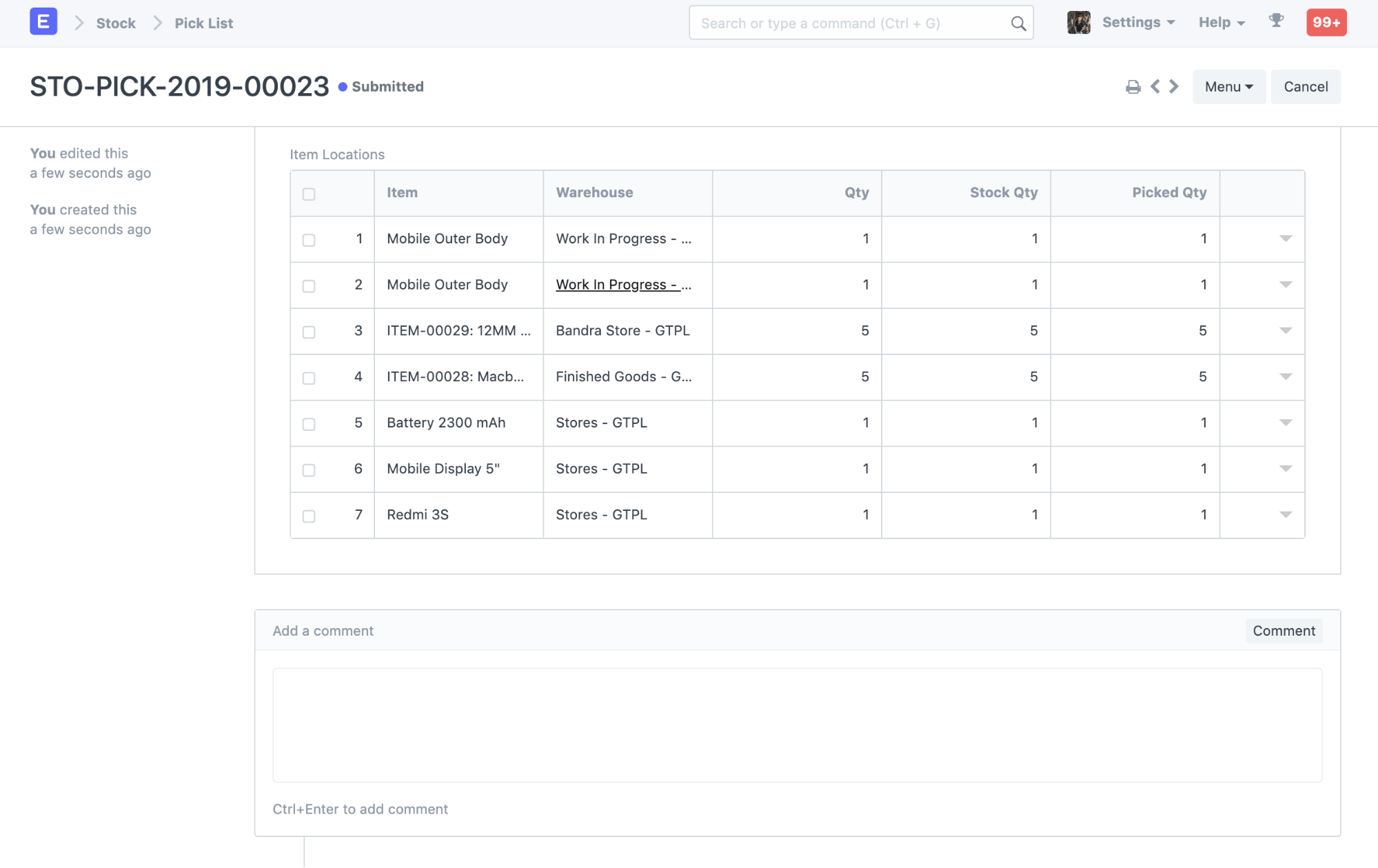

You can pick items from different warehouses. Moreover, if the items are serialized, you can also choose the serial numbers which will fulfill the order.

In ERPNext, the batches close to expiry are automatically selected when using the Pick List feature shown above.

Conclusion

Like we discussed, we saw how inventory control is linked to better revenues and business growth. By making use of the right data and some software, you ensure stock availability within warehouses and timely order fulfilment.

In this blog, we first understood what inventory control is and it’s objectives, then we saw the methods used for inventory control. We briefly touched on how inventory control is different from inventory management, and finally saw how to use software to control inventory with advanced features and reports.

Editing note 04/11/2020: This article previously reflected ambiguous information around inventory control and inventory management. It has been updated to show clear distinctions and also better information under inventory control methods.

Prasad Ramesh

Marketing at Frappe.

@Prasad

Would appreciate if you create content on Demand Driven Materials Requirements Planning.

Check out website of Demand Driven Institute.